How to Specify Custom Rigid Boxes

Your 4-step help guide to custom rigid box formats, fitments, materials, print processes and embellishments.

Luxury rigid packaging

Rigid boxes are synonymous with luxury packaging and precision manufacturing. Whether you’re a brand owner, designer, or buyer sourcing rigid box manufacturing for premium retail or promotional packaging, this guide explains how to plan and specify your rigid box for production.

At Progress, we’ve been manufacturing custom rigid packaging for more than 25 years – supporting brands in beauty, fragrance, fashion, drinks, tech, and homeware with expert advice on materials, construction, and finishing. From paper-over-board boxes to our exclusive eco-friendly V-FORM production process, our experience in luxury rigid box manufacture ensures every project is produced to the highest standard.

Step 1:

Choose a Format & Size

Getting started

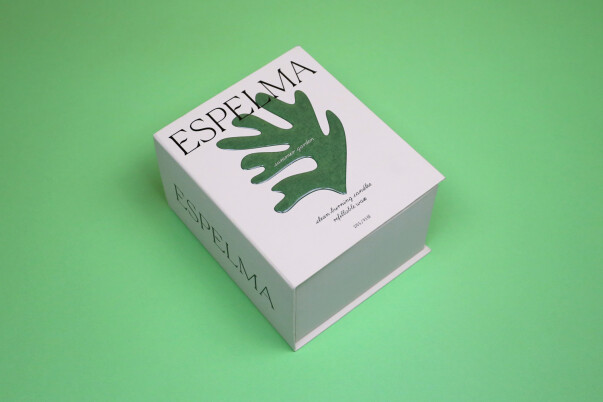

At the early stages of specifying your rigid box for production, it’s important to establish the right format and size for your custom rigid box. Think about what’s being packed, how it will be presented, which box structure will best suit your product and manufacturing requirements, and also assess the importance of its eco‑friendly credentials. Getting these fundamentals right ensures efficiency in rigid box production across industries such as beauty, fashion, drinks, and technology.

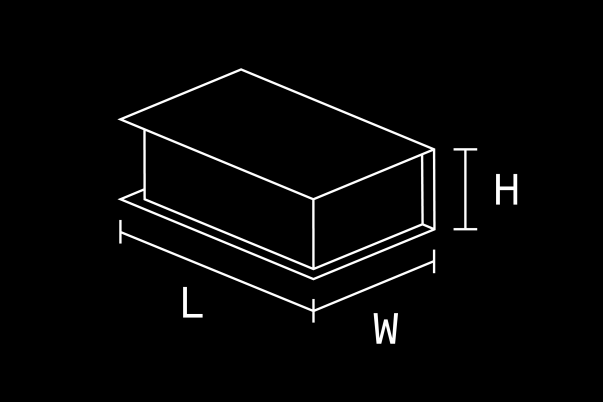

Measuring your box

Sustainability of your box

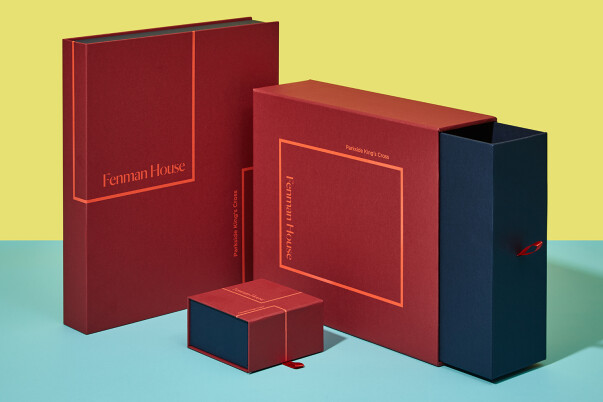

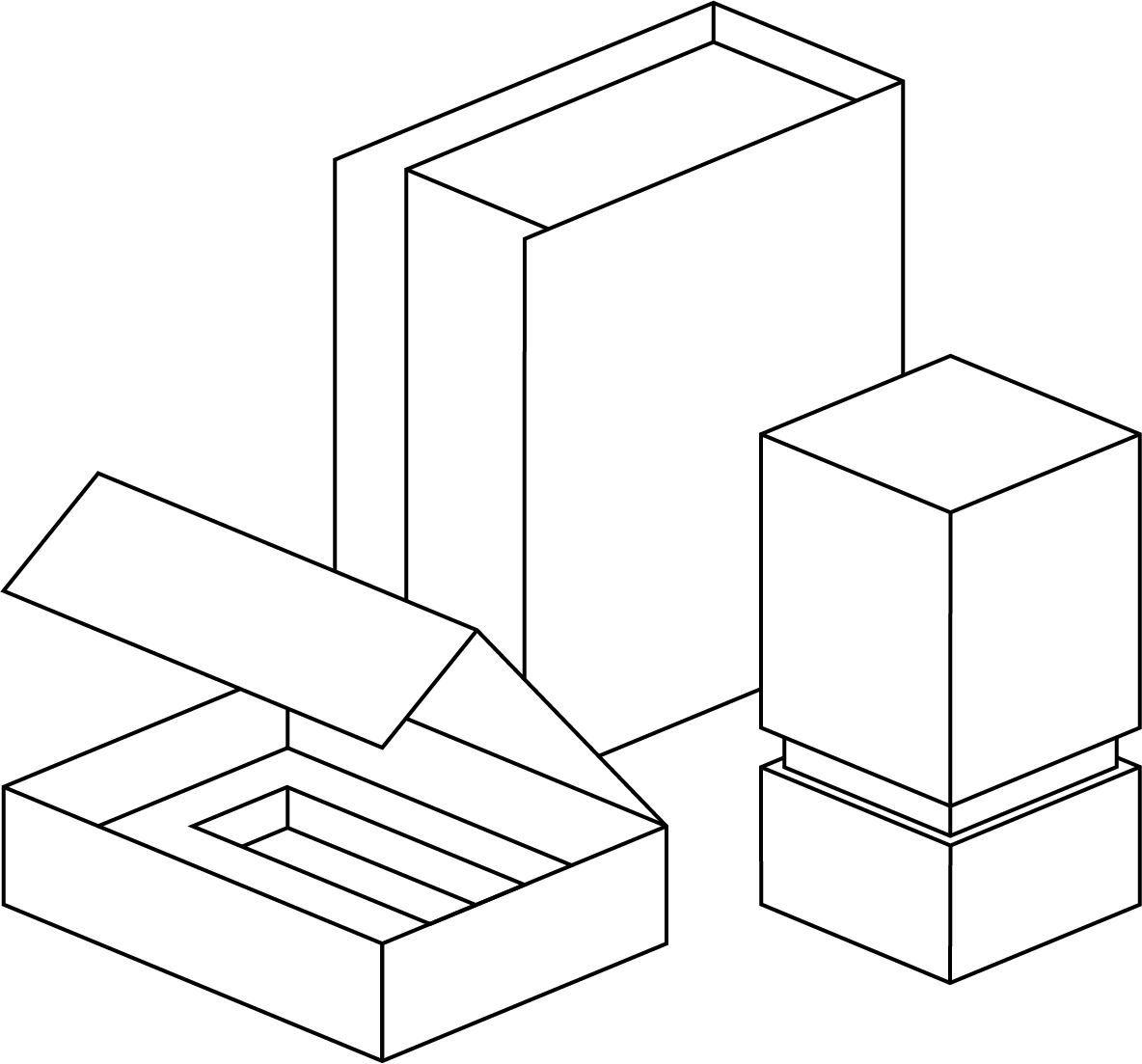

Box Formats

Rigid boxes can be produced in various structural styles, each offering distinct manufacturing and presentation benefits:

Box & Lid / 2 piece box

Shoulder box

3 board case & tray box

4 board case & tray box

Clamshell box

Drawer / Tray & Sleeve box

Collapsible Box

Tube Packaging

Custom Construction box

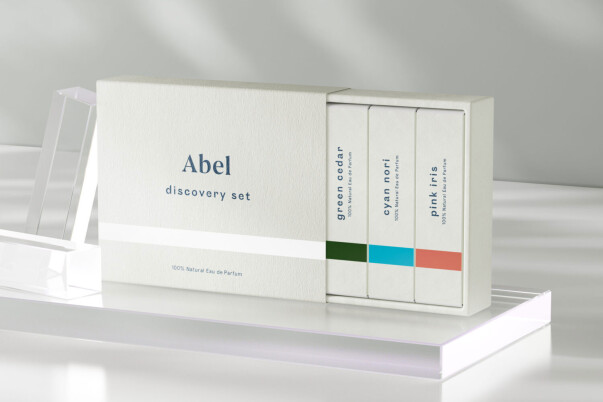

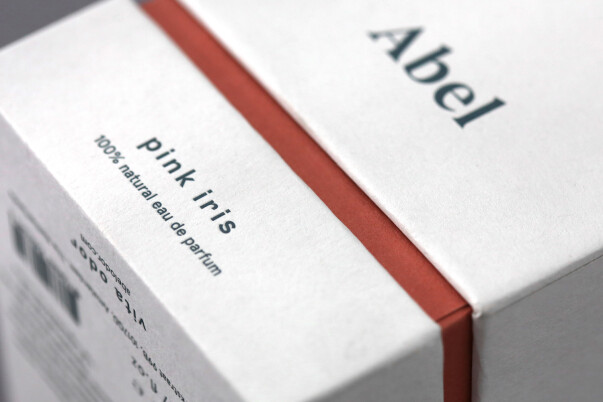

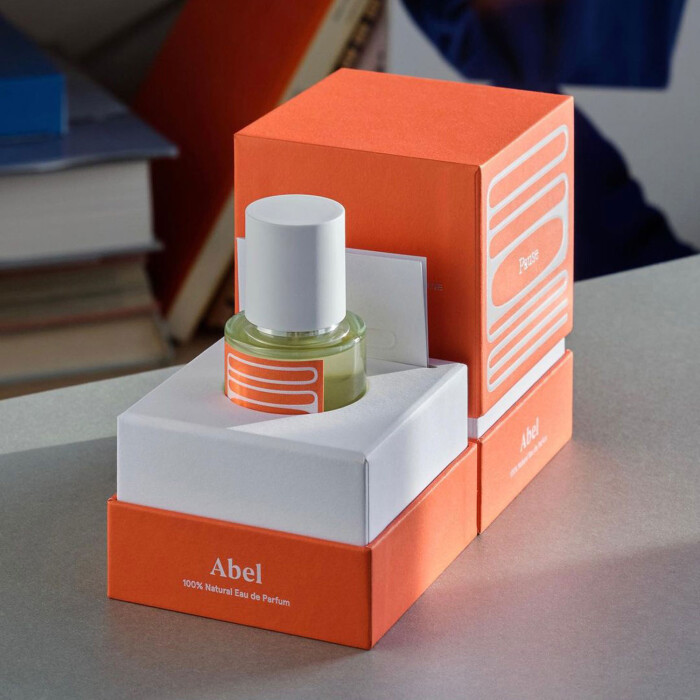

Custom shoulder box fragrance packaging for Abel, with a featured indent around the rigid box.

Luxury 4-board case and tray rigid box with a hinged-lid for The Doyle Collection.

Custom clamshell rigid box with a printed inner for fragrance brand Side Story.

Custom tube packaging for Sunspel, made from greyboard, covered in embossed Kraft paper.

Step 2:

Add a Fitment or Closure

Fitments and closures are integral to the production process, helping protect your products while enhancing the final presentation for sectors such as beauty, drinks, fashion, and technology.

Box Fitments

Fitments are key to internal packaging design, ensuring each product is displayed securely during shipping and retail handling. Our team can advise on which manufacturing method and material will best suit your needs.

Greyboard Fitments

Corrugate inserts

Carton Inserts

Foam Fitments

Vacuum-Formed Trays

Paper Pulp Inserts

Wool & Felt Protection

Post-Consumer Waste Fitments

Mushroom Grown Inserts

Void Fill

Box Closures

Closures add functionality and finesse to rigid box manufacturing, completing the final stage of production.

Tabs

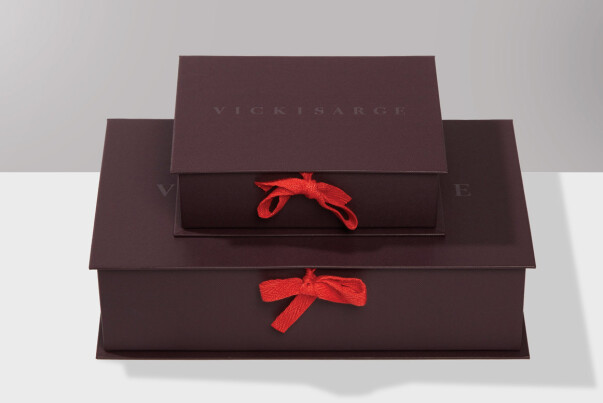

Ribbon & Paper Ties

Magnetic Closures

Custom carton insert made using FSC® papers to package a fragrance range for Bath House.

Custom ribbon tie to add a luxurious and premium finish to this rigid box for Thom Laurence.

Step 3:

Specify a Production Process & Material

All rigid box manufacturing begins with high-quality greyboard – a recycled, durable material that forms the box’s solid structure. The chosen manufacturing process and materials define the strength, sustainability, and overall finish.

Paper over board rigid Boxes

The production process involves wrapping die-cut greyboard with a selected paper or covering material. It’s the most popular technique in luxury rigid box manufacturing, offering limitless options for brands to achieve the perfect production finish.

Uncoated Papers

Coated Papers

Recycled Papers

Specialist Papers & Creative Coverings

Bespoke Papers

V-form rigid boxes

Our innovative and exclusive V-FORM process streamlines manufacturing by scoring directly into the board to form perfect 90° folds. It reduces materials, improves recyclability, and maintains a luxury aesthetic – ideal for brands seeking sustainable box production.

Premium greyboard (Recycled / FSC Certified)

Duplexed or Laminated Boards

Recycled & Alternative Fibres

Litho printed white kraft uncoated paper used on luxury rigid fragrance packaging boxes for Abel.

Recycled Notpla paper made from waste seaweed biomass, used on luxury watch packaging for Fiona Krüger.

Collapsible rigid box for Markus Lupfer covered in specialist holographic mirrored paper.

Custom V-FORM rigid boxes for Joseph Giles manufactured using Eska heavy-weight recycled board.

Step 4:

Select Printing, Finishing & Embellishments

Our specialist printing and finishing services for rigid boxes set us apart as experts in the production of branded luxury packaging. Progress combine technical capability and craftsmanship to deliver high-quality results for brands across beauty, fashion, drinks, tech, and homeware.

Printing Processes

Your print choices define how a brand comes to life across your packaging. The right process can elevate simple designs, highlight texture, and ensure colour consistency across every box and sleeve.

Offset litho print

Screen print

Water based inks

Pantone matching

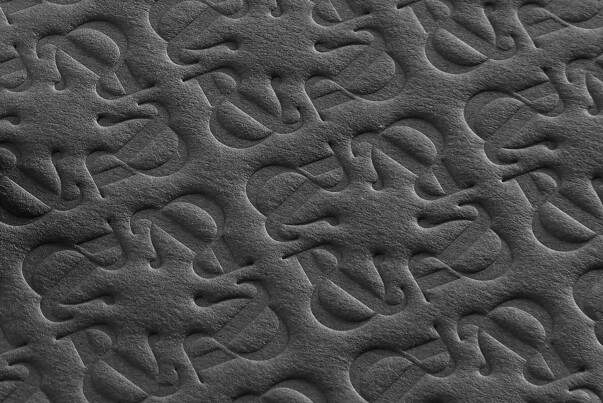

Finishing Processes

Finishes add tactile quality and visual depth, transforming packaging from functional to memorable. They help communicate quality and enhance the perceived value of your brand.

Foiling

Blind emboss / deboss

Lamination

Spot UV

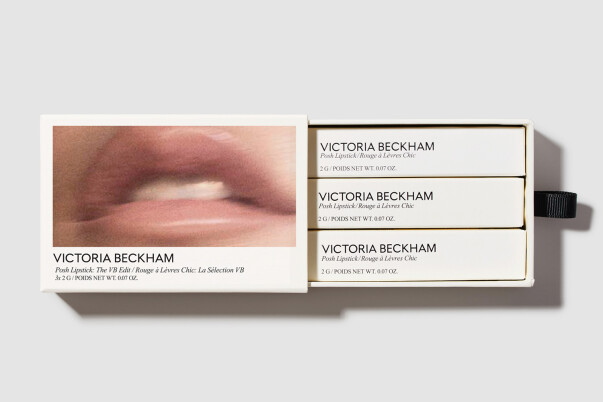

Packaging Embellishments

Embellishments provide the final touches that personalise and refine your packaging. These elements add distinction, elevate unboxing experiences, and reinforce the craft behind your product presentation.

Ribbons & Pull Tabs

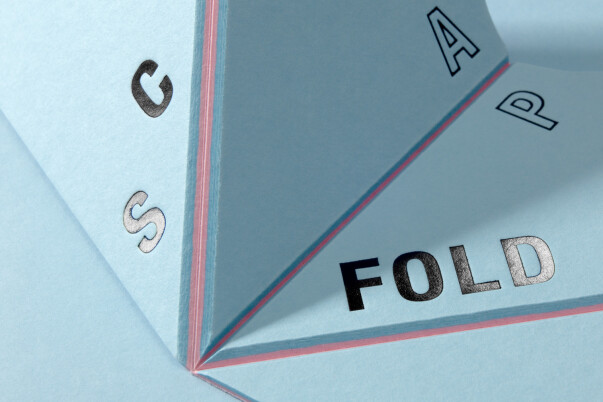

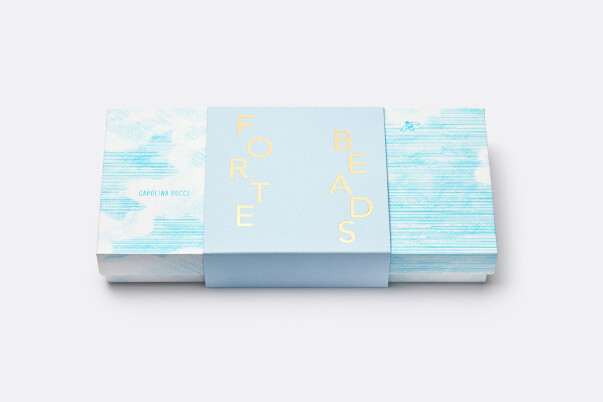

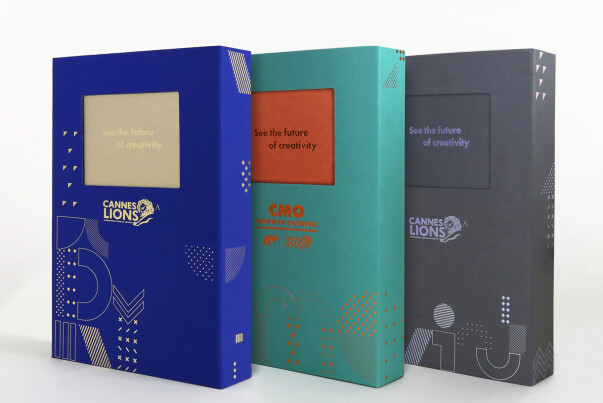

Sleeves & Belly Bands

Tags, Badges & Plaques

Windows

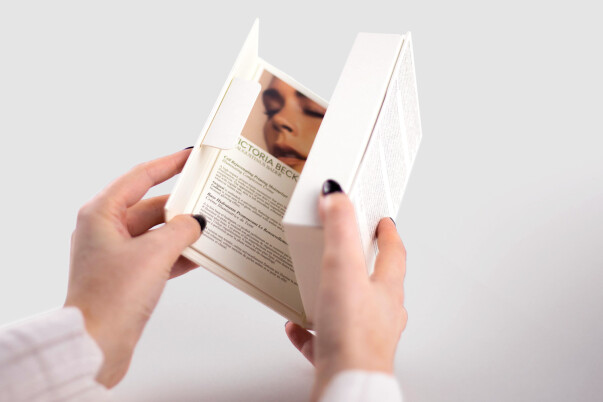

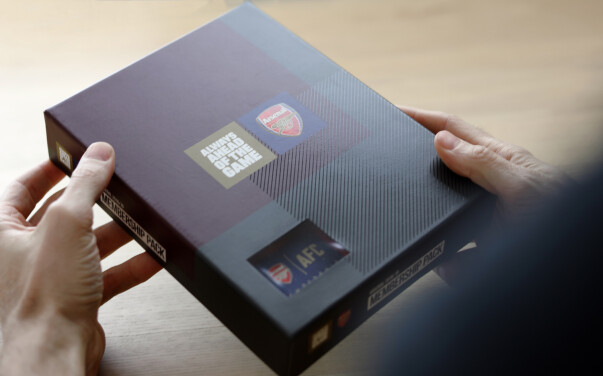

Luxurious ribbon pull tab on a custom rigid box for Victoria Beckham.

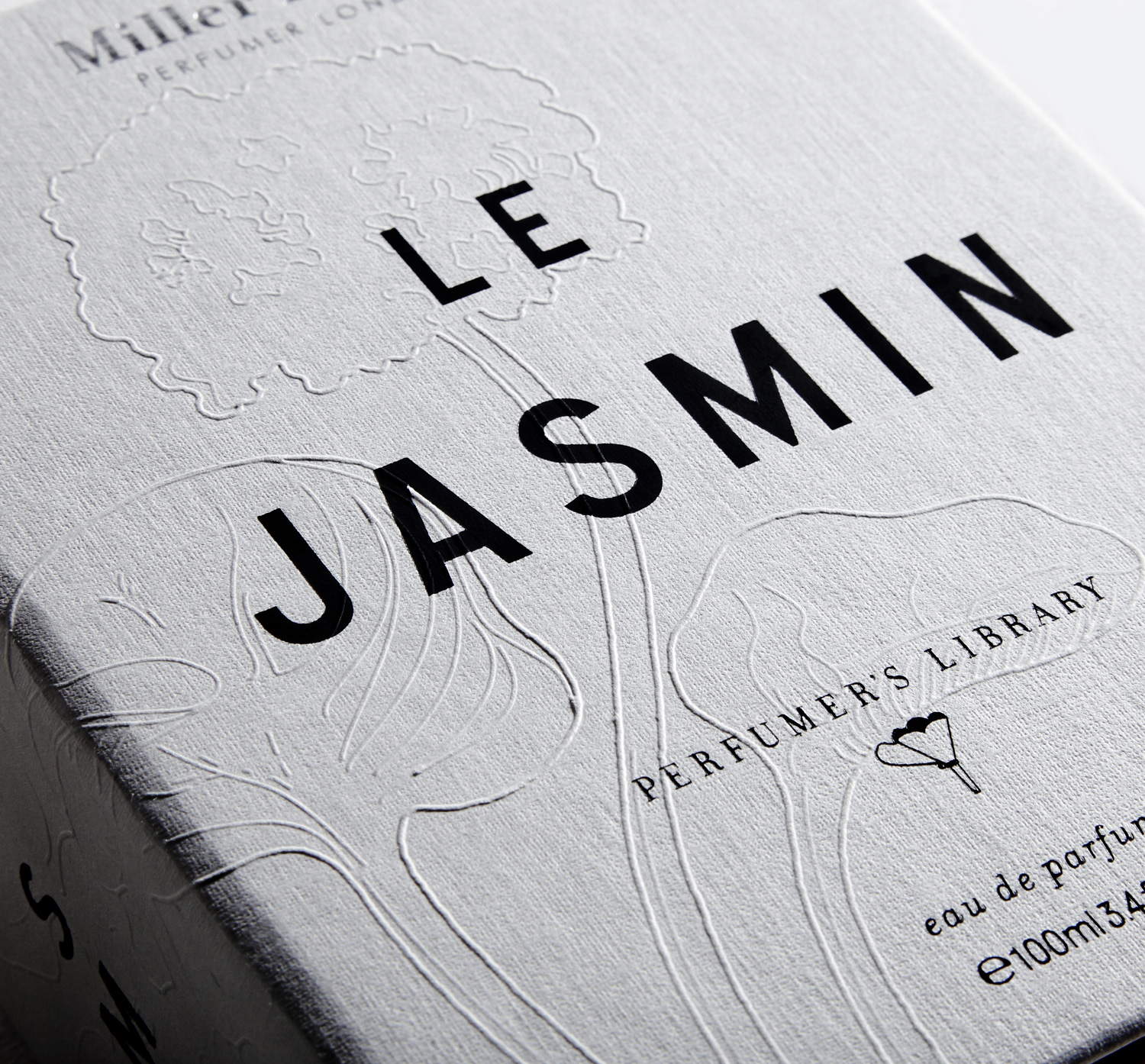

A tactile and visually striking blind emboss print finish on a range of luxury perfumes for Miller Harris.