Side Story

Each bottle of Side Story perfume begins its journey in Grasse, Provence, and is produced alongside a network of independent artisans. Defiantly opposed to the use of plastic in their fragrance packaging, the perfumes are bottled sustainably in soda glass and sealed with handcrafted marble lids that can be recycled or reused. Their century-old production facility, farmers, distillers, compounders, stonemasons, label makers, and designers are scattered across the globe.

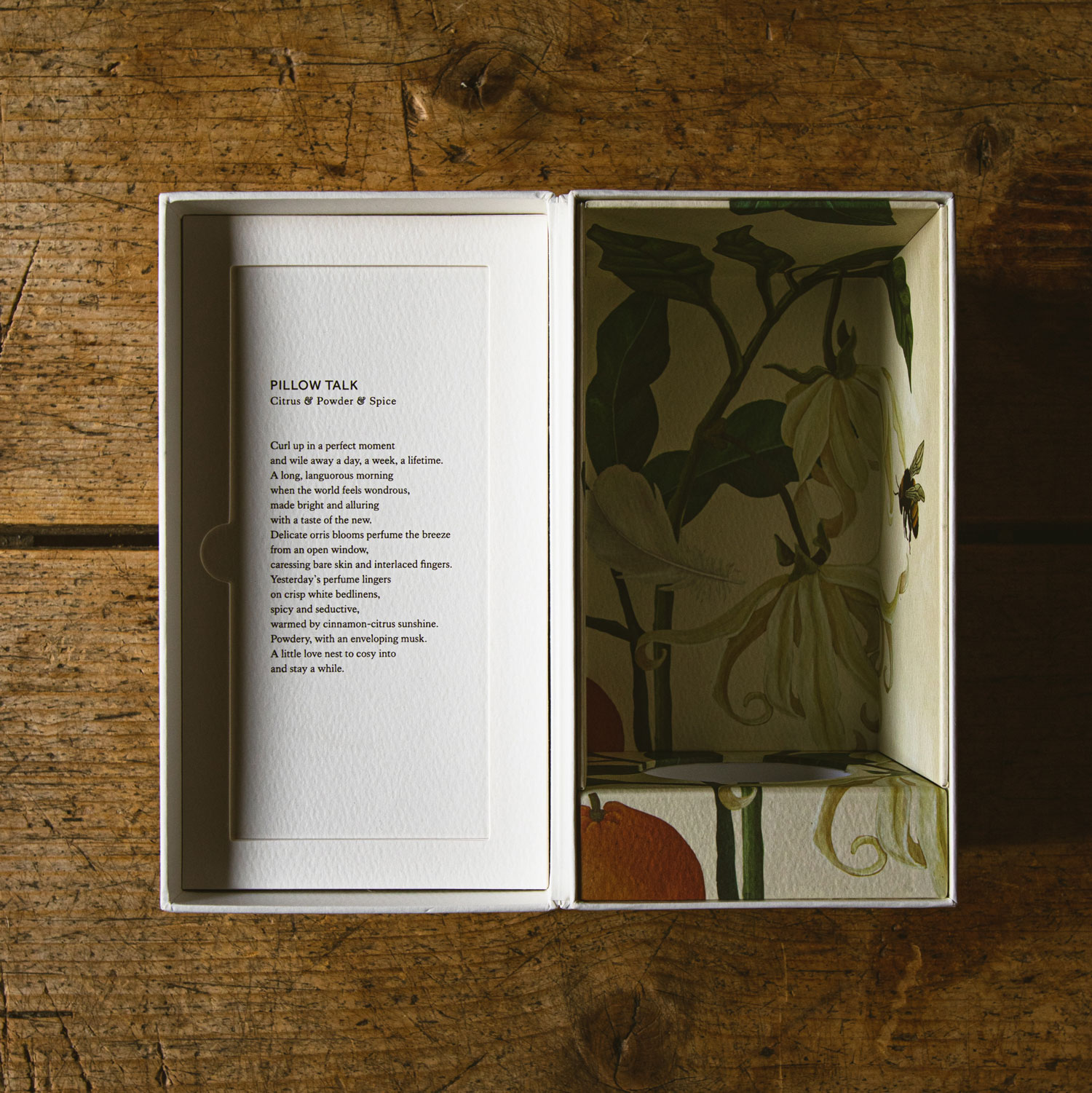

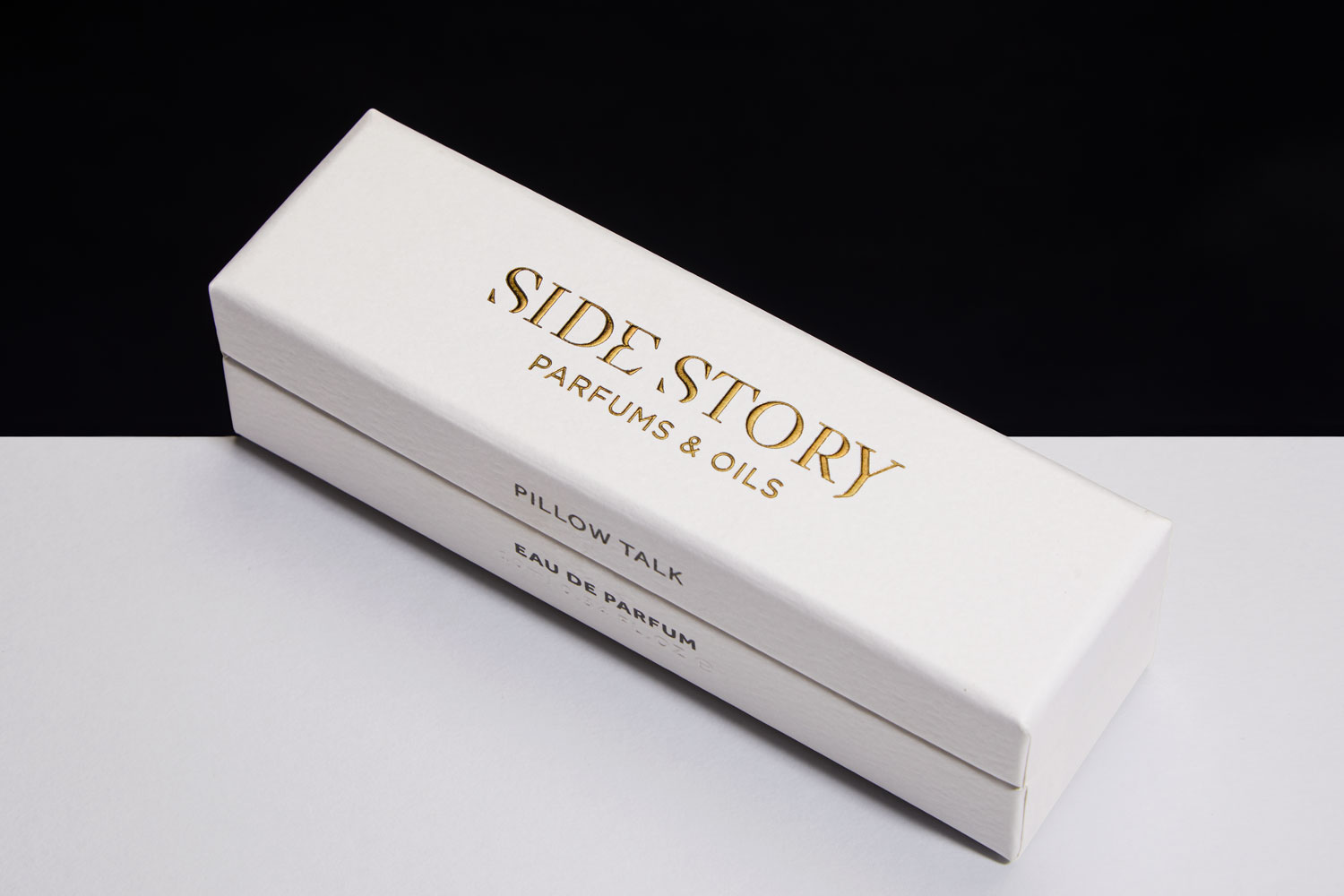

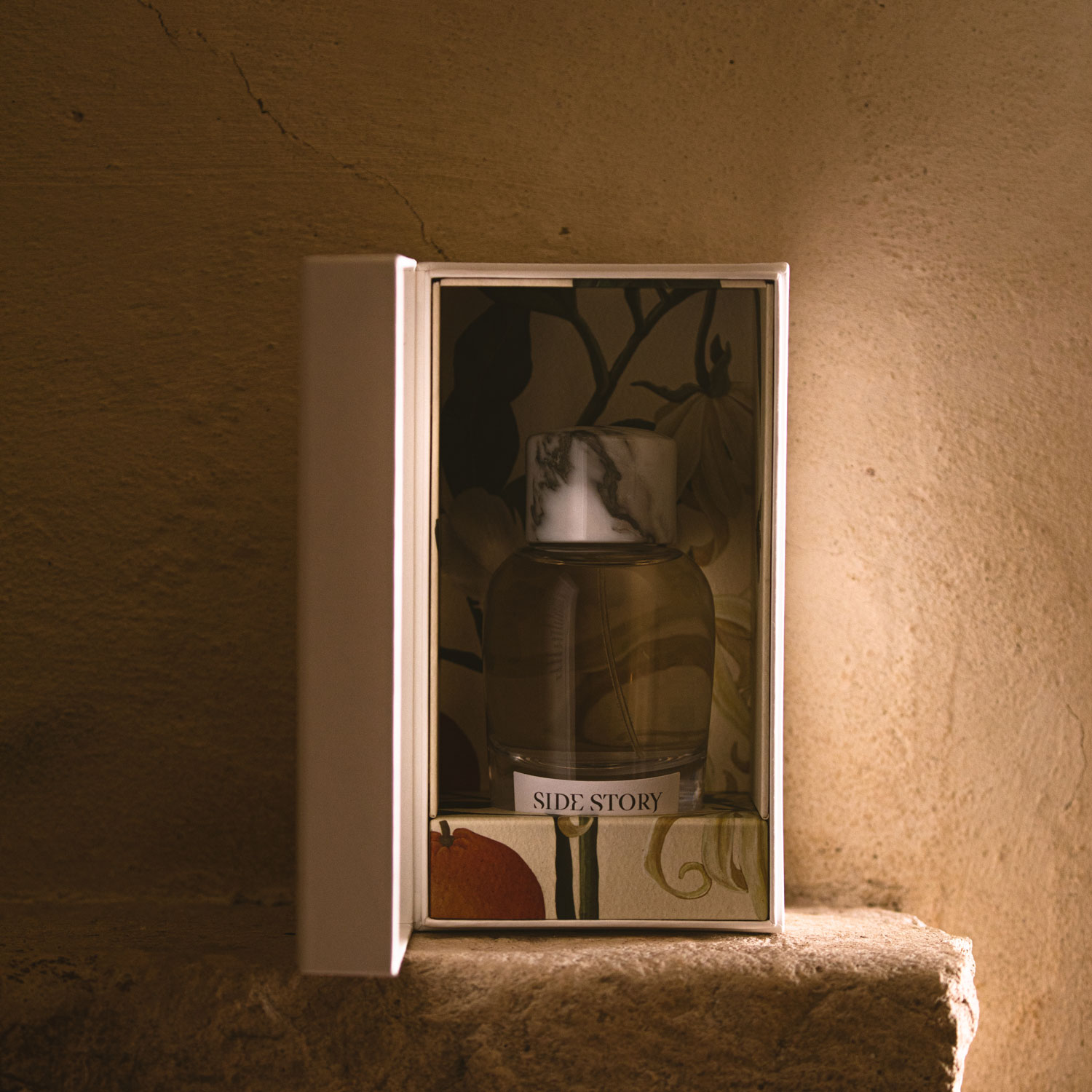

Progress worked with the brand to manufacture both their custom rigid boxes and corrugate delivery boxes across a range of bottle sizes for six different fragrances. This included their 7.5ml taster bottles all the way up to their 100ml full-size packs, which were packaged in sets with matching full colour printed inners and outers. A textured paper stock was selected for the outsides of the rigid boxes and paired with litho printed inners to showcase their sumptuous image branding on the shoulder of the box. External production details on these boxes included blind-embossed and debossed panels, using custom-made foils.

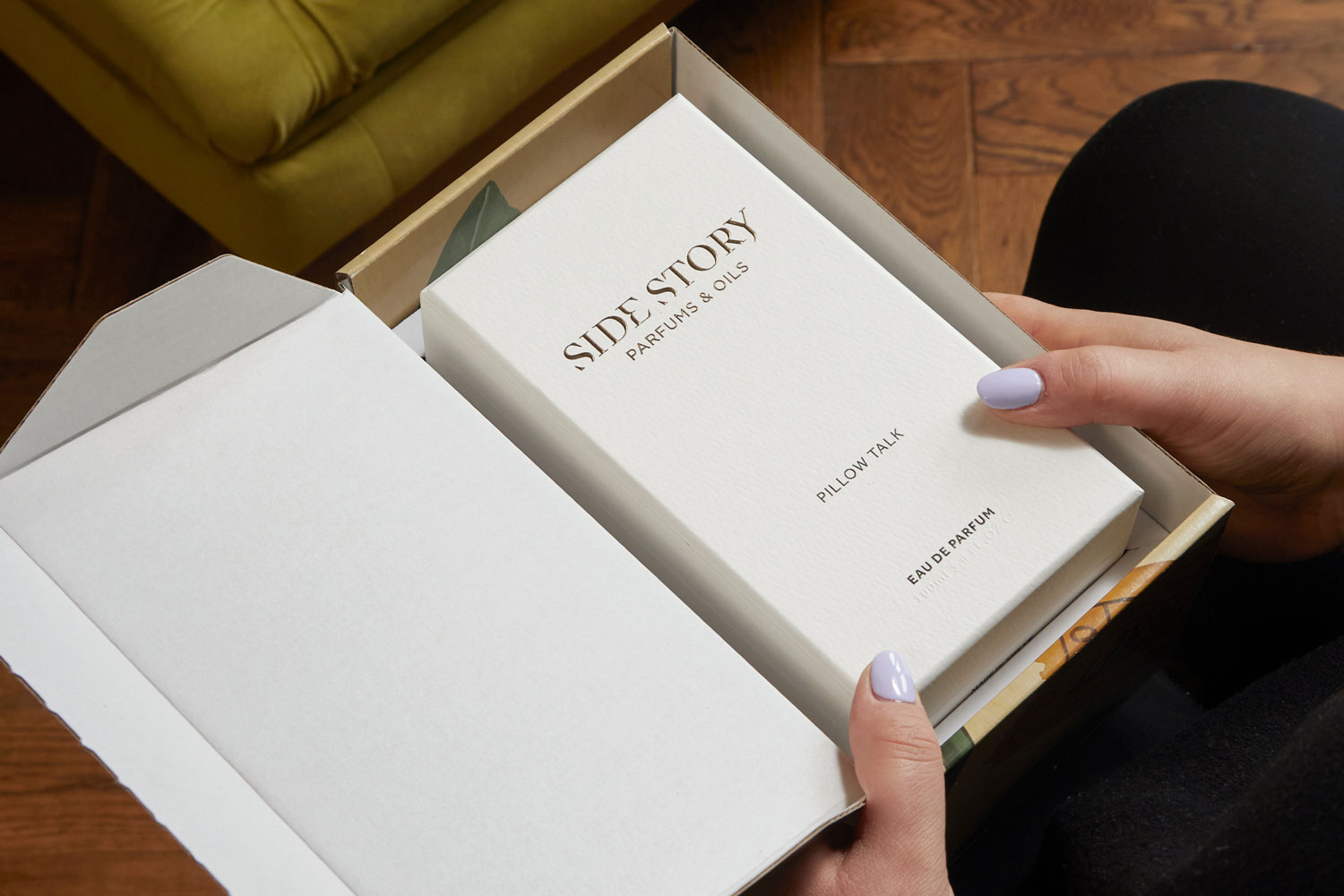

The accompanying custom delivery boxes were produced using a colour-matched paper which was laminated to the inner face of the corrugate to coordinate with the litho printed outsides. A crocodile tear-strip opening on the front face and hinged-lid box format give a seductive reveal to the bottles as well as adding layering and a theatrical experience to the opening.

Project photography by Guy Farrow and Side Story.

SUSTAINABILITY

Fully recyclable packaging. Globally FSC® certified, sustainable and responsibly sourced materials.

A textured paper stock was selected for the signature perfume packaging boxes and paired with litho printed inners to help contrast and showcase the sumptuous imagery.