For more than a decade, Abel and Progress Packaging have worked in close partnership, developing packaging that reflects a shared belief in long-term thinking, responsible material choices and clarity of intent. Across multiple fragrance projects, this relationship has continually evolved – each iteration refining how premium perfume packaging can be manufactured with both integrity and restraint.

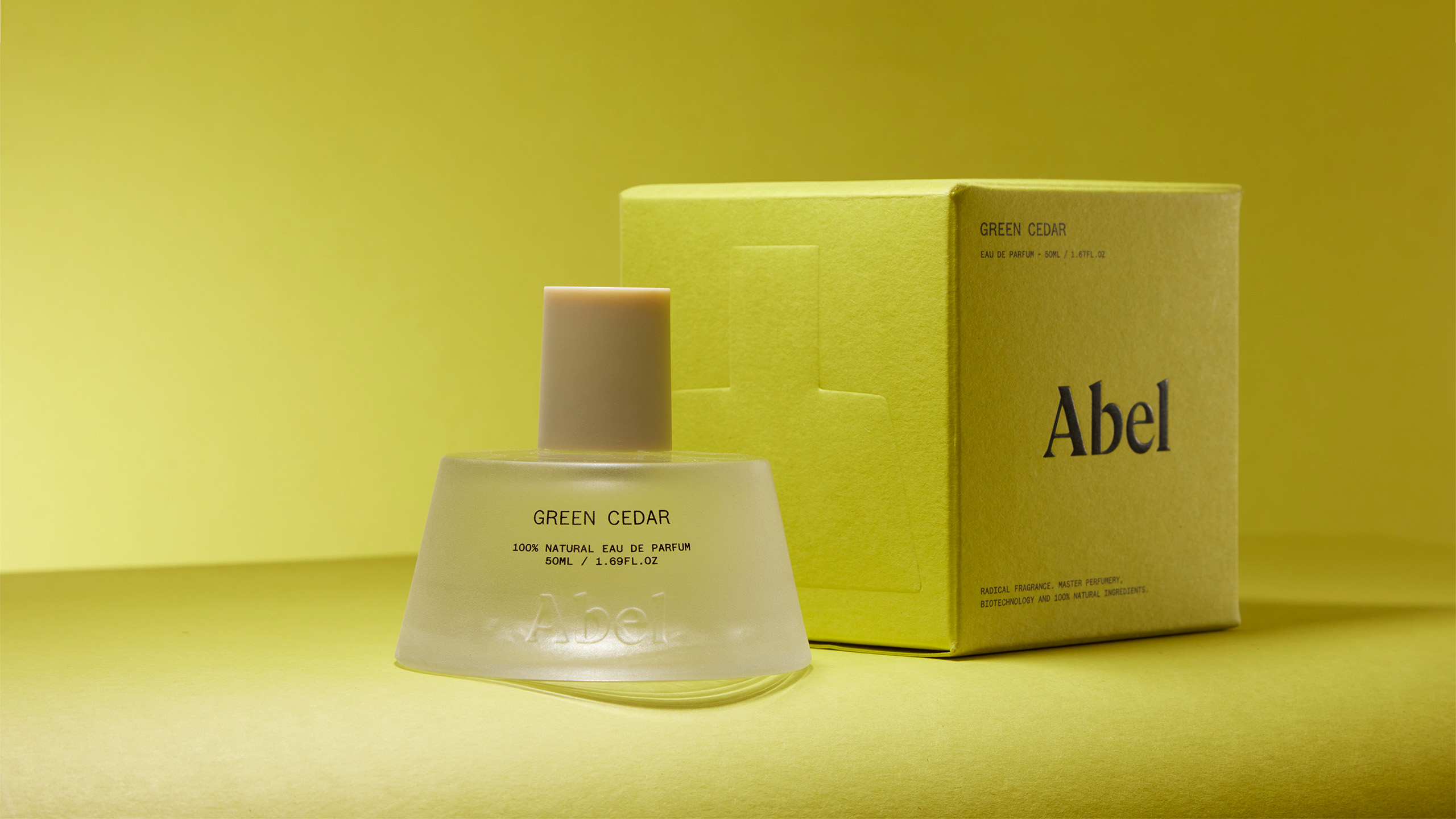

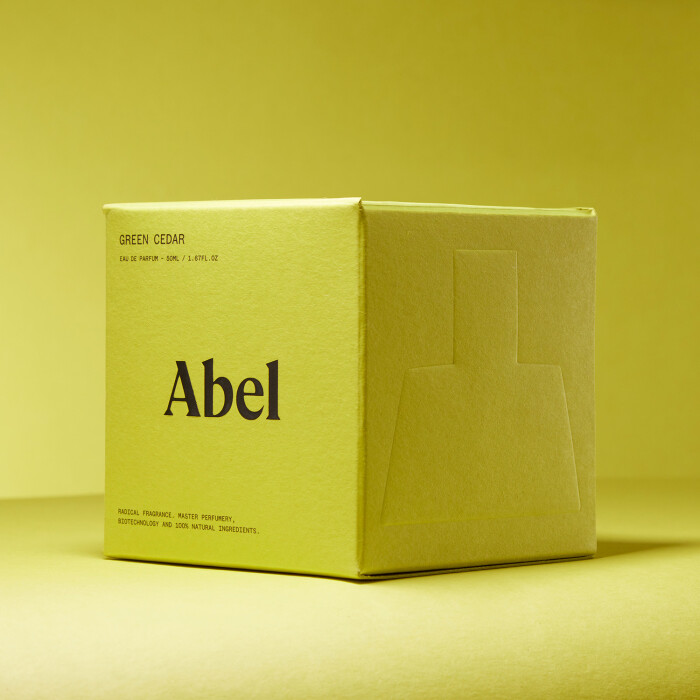

The latest project accompanies Abel’s reformulated fragrance range and showcases their refreshed brand identity and packaging by Base Design. While the scents themselves have been reimagined through advances in biotechnology and natural perfumery, the packaging reflects an equally deliberate shift. Rather than relying on conventional luxury rigid boxes, the new range moves towards a carton-based format – one that uses less material, simplifies construction and allows paper to play a far more central role in defining brand character.

At the heart of this change is a bespoke paper, specified and manufactured exclusively for Abel, and used consistently across the entire fragrance range.

One of the defining elements of this latest project – with the whole process managed throughout by Progress – is the development of a custom-coloured paper, created to give Abel’s packaging a soft, understated elegance while delivering clear environmental benefits. Rather than treating sustainability as an add-on, the paper itself was developed to align with the brand’s values from the outset.

Manufactured in the UK using 100% recycled fibre, the paper combines 75% post-consumer waste with 25% reclaimed material from used coffee cups. Through a carefully controlled manufacturing process, these fibres are refined and blended into a premium-grade substrate that delivers the strength, consistency and surface quality required for luxury fragrance packaging.

Compared with more conventional paper stocks and construction typically used in premium packaging, the bespoke paper and carton construction achieves up to a 95% reduction in carbon footprint. For brands and designers, this demonstrates how early, informed decisions around materials – guided by experienced packaging manufacturing specialists – can deliver measurable environmental benefits without compromising aesthetic quality or customer experience.

Paper making, bespoke colour testing and sampling.

Raw material awaiting conversion. Abel’s custom paper for their packaging is made from 25% recycled coffee cups.

Abel’s bespoke paper for their packaging is made from 75% post consumer waste.

Recycled papers are often assumed to limit creative or technical possibilities, particularly in luxury applications. This project challenges that perception. Progress worked closely with leading paper makers James Cropper, whose expertise in fibre recovery and paper manufacturing enables post-consumer materials to be transformed into refined, high-performance substrates.

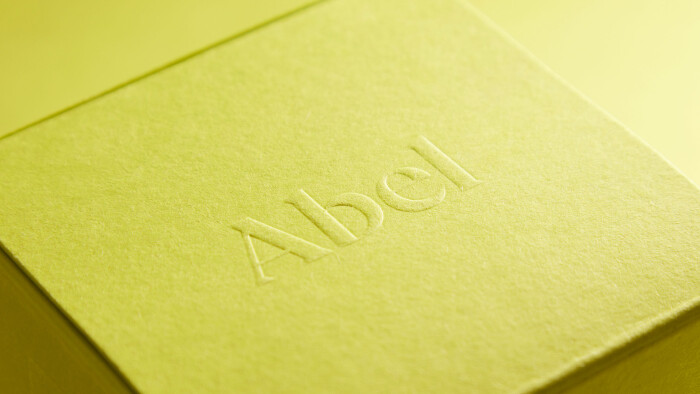

At scale, fibres are carefully sorted, cleaned and processed to ensure consistency, strength and reliable print performance. This allows the paper to support detailed embossing, debossing and restrained foil finishes, while retaining a natural tactility that reinforces Abel’s understated brand language.

For Progress, involvement at this stage of the supply chain is critical. By working closely with paper manufacturers and specifying materials at fibre level, Progress helps brands and designers understand how paper choice affects not just sustainability credentials, but manufacturability, performance and finish throughout the production process

Carton box showing matt black foil finish and bottle silhouette embossing detail.

The uncoated mono-material and plant-based inks ensures the carton boxes can be recycled after use.

A key decision within the project was the move away from traditional paper-over-board rigid boxes in favour of carton formats manufactured from a single bespoke substrate. By reducing material layers and simplifying construction, the packaging system improves recyclability while maintaining a premium look and feel.

Progress currently manufactures multiple carton sizes and SKU variants within the range, specifying different paper weights to suit each format and engineering the structures to protect the glass fragrance bottles during storage and transit. Subtle detailing – such as blind embossing, raised emboss and matte foil finishes – allows the paper itself to take centre stage, reinforcing both tactility and brand distinction.

For fragrance, beauty and luxury brands exploring alternatives to rigid boxes, this project demonstrates how cartons can deliver equivalent brand value and customer experience, with added environmental benefits. As fragrance packaging manufacturing specialists, Progress continues to support clients through these transitions – helping translate creative ambition into responsible, scalable packaging solutions built to perform.

A custom engineered inner fitment holds the bottle securely in place inside the carton box.

Blind emboss brand logo on the carton lid adds a sensorial tactility to the box.

This latest range builds on a long-standing relationship between Abel and Progress, following earlier projects that explored recyclable fragrance cartons and mono-material packaging systems. Previous collaborations, such as the Abel Pause project, investigated similar principles around material reduction and responsible specification, with each project refining how luxury fragrance packaging can be manufactured with less complexity and greater intent.

See the case study find out more about our latest luxury custom carton packaging project for Abel.

Frances Shoemack, Abel founder.

Founder, Frances Shoemack (left), with the Abel team.

Abel Pause rigid shoulder format boxes manufactured by Progress.

If you’re interested in exploring custom and unique coloured paper, or alternative packaging formats to reduce impact without compromising brand value, our team can help guide you through the material, manufacturing and production considerations. Get in touch to discuss what’s possible for your packaging.