Printing

Print is the means by which we transfer a brand or design onto a packaging format, and there are many different processes available to allow for an array of materials to be personalised. Our experience in this area allows us to develop and deliver the best process for your brand.

At its simplest, printing one colour we use Pantone printing to deliver consistent branding across the packaging pieces. More complex, multicolour designs and imagery, however, require careful control to deliver a powerful branded message through intricate yet clear design.

There are many different ways to include print into your packaging. From screen print to litho, gravure print to digital, while not forgetting 3D printing, we determine the best production process for the job once the design has been presented to us. Specialist materials such as fabrics and metals require specialist processes, also. We can use dye sublimation as well as image transfers to achieve print finishes on such items.

PACKAGING

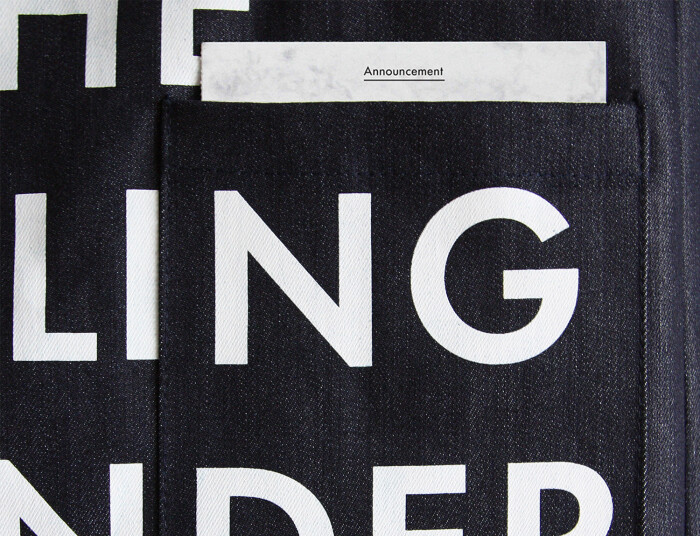

Denim tote bag

MATERIAL / PROCESS

Raw denim, woven label, screen print, hand finish.

PARTNER

Commission

PACKAGING

Bespoke paper carrier bag

MATERIAL / PROCESS

Dyed uncoated paper, dyed ribbon, screen print, foil block, hand make.

PARTNER

Harrods

PACKAGING

Polypropylene retail packaging

MATERIAL / PROCESS

500 micron frosted polypropylene, flood tint, litho print, die-cut, glue.

PARTNER

James Brown London

PACKAGING

Luxury retail bag

MATERIAL / PROCESS

Grosgrain ribbon, uncoated white Kraft paper, litho print, laminate.

PARTNER

Aultmore

PACKAGING

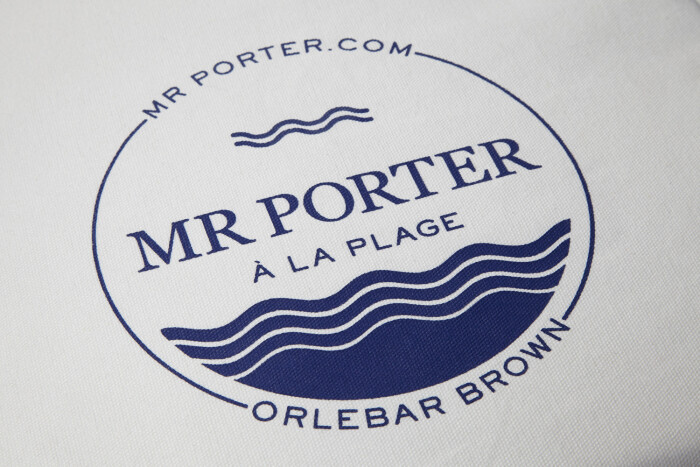

Promotional tote bag

MATERIAL / PROCESS

16 oz canvas, custom dye, screen print, machine stitch.

PARTNER

Mr Porter