Step 1:

Choose a box type / format

When designing your custom cardboard box you’ll need to start by deciding on the format, based on what the box is going to package and how it will be used.

Corrugated e-commerce boxes usually work well with a hinged lid and tear-strip opening, whereas transit packing cases require an open flap top and internal compartments to enable them to be quickly filled and then sealed closed. However the box is going to be used, the demands that will be put upon its performance need to be carefully considered.

Getting started

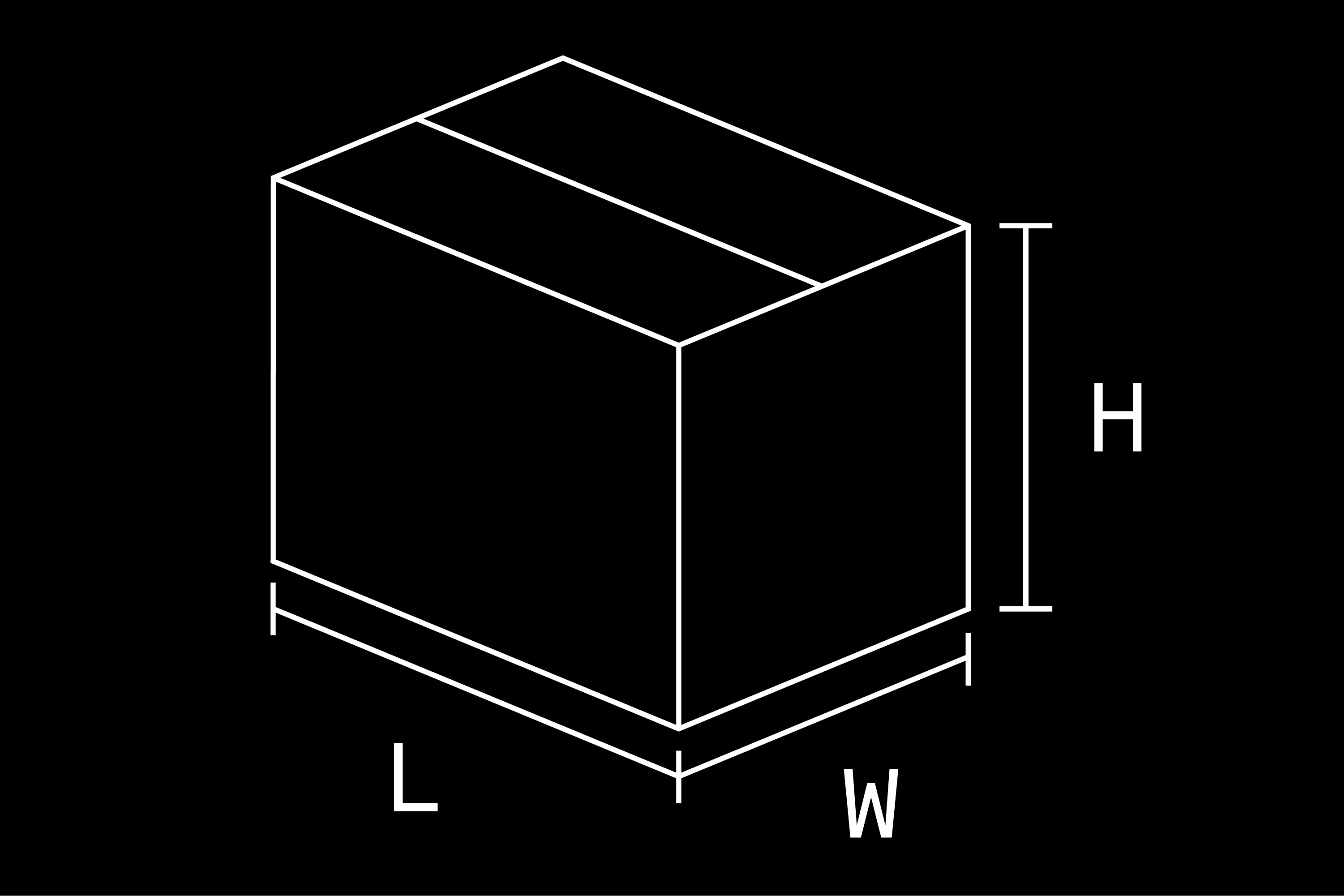

Before looking more closely at the design details, you’ll need to make measurements to define the size of box you need and also asses the importance of its eco-friendly credentials, as this will relate to the specific grade of corrugated material that you choose for manufacturing.

Boxes are measured using Length (L) x Width (W) x Height (H). When specifying the dimensions for a box it’s important to be clear about the measurements. It’s also worth considering the products that are going to be packaged, to ensure that there’s enough room to protect them. We can assist with this to ensure that your products are not overpacked – helping to avoid unnecessary material wastage in manufacturing.

Sustainability of your box

Corrugated flute board is one of the most sustainable packaging materials available. The central layers of the corrugate are made with a high percentage of recycled material, whilst the carrier layers, above and below, are ‘virgin fibre’ and are normally FSC® certified. This affords you full confidence regarding the eco-friendly credentials of your box. It’s best to avoid any post-printing film lamination processes to ensure your box is both made using materials from sustainable sources, and is fully recyclable after use. For more information about FSC certifying your corrugate packaging please refer to our Packaging Standards insight.

Box type / format

A good reference point for looking at different cardboard box formats is the FEFCO catalogue (The European Federation of Corrugated Board Manufacturers). This catalogue includes thousands of styles of retail and e-commerce packaging, and packing cases – all of which are individually identified by a 4 digit code. These styles can be adapted to suit the size of most products and their codes are a universal point of reference regarding specification. In terms of inserts to secure the products inside your box, if required, they are best customised to suit the exact shape and size of the contents.

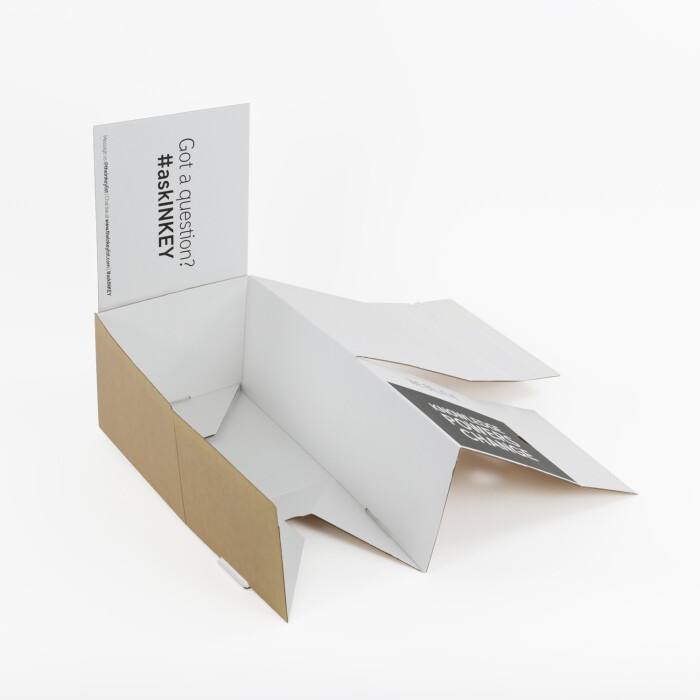

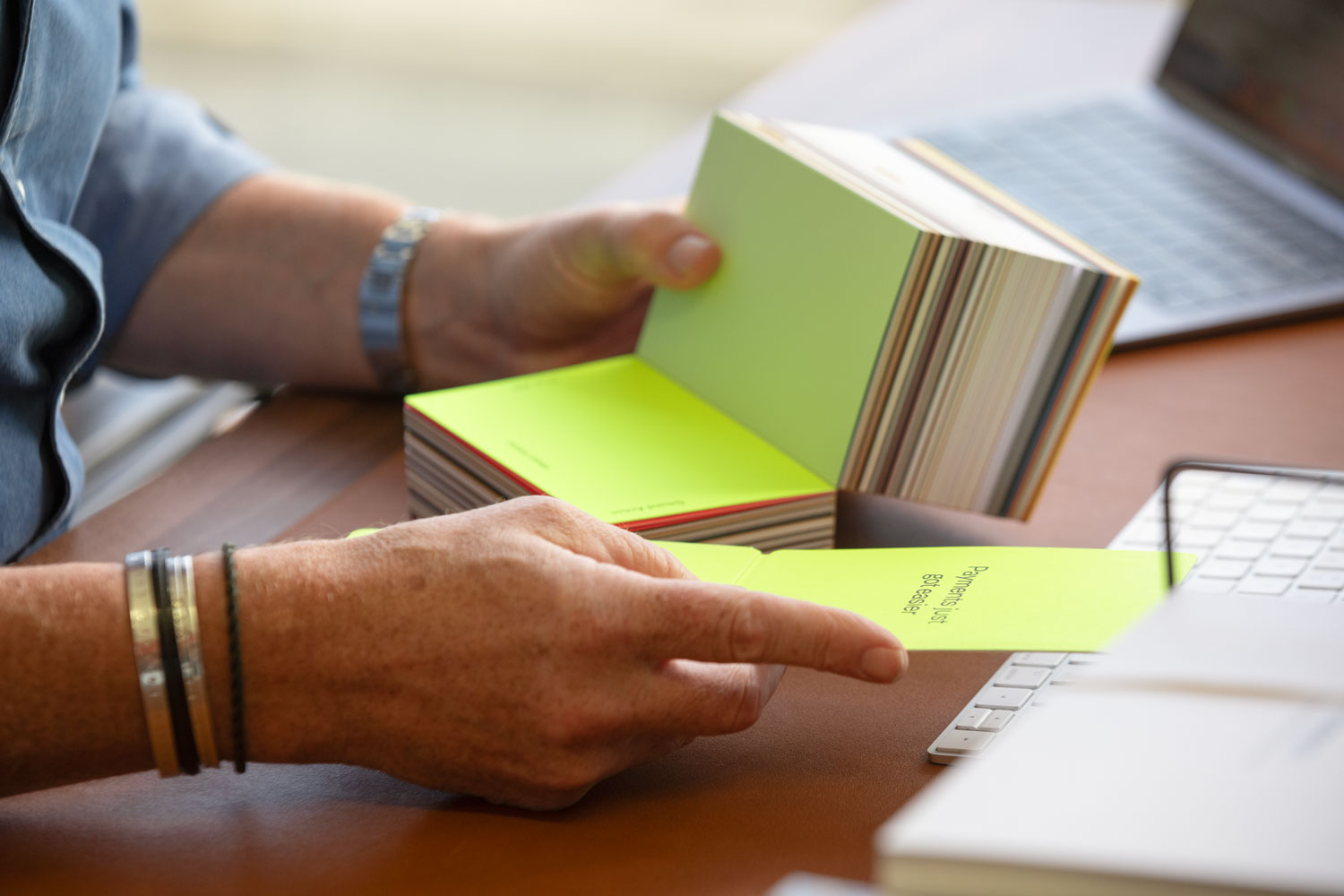

Retail and e-commerce boxes

Packaging demand in the retail and e-commerce sectors has surged in recent years. To coincide with this, the versatility of corrugated board, along with developing digital printing techniques, now enables us to make packaging that is perfectly engineered for transportation while also being an enriching brand touch point for the consumer. Often landscape in format with a lift-up lid, this type of packaging provides multiple options for customising your branding and layering the unveiling process to access the product inside. To add to the theatre of opening you can incorporate tear-strip openings and branded interior flaps to enhance the journey. If product returns are integral to your process, resealable closures can also easily be incorporated.

Cardboard packing case boxes are a more functional packaging format, often tailored to the safe transportation of goods rather than seductive consumer experience. These box formats are usually made using thicker corrugate flute material and feature flaps to both the base and lid which can either be taped closed or incorporate a slotted closure mechanism. A number of printed branding options are available for this type of box, enabling them to be used at point of sale if required.

We offer a wide range of fully customisable, eco-friendly and sustainable corrugate box inserts. We can manufacture inserts, or dividers (if packaging multiple products in the same pack), to match materials used on the outside of your box to improve presentation. We can also manufacture other more eco-friendly options in larger volumes, including loose-fill, moulded pulp paper inserts and even custom grown biodegradable mushroom-based packaging.

Step 2:

Select a print process

When producing custom corrugated cardboard boxes, one of the most challenging aspects can be deciding on the best printing process to use.

Selecting the print process largely depends upon your visual branding – whether linear, photographic, full colour or single colour in style. If you’re looking for a more cost-effective custom corrugated box it’s best to print directly onto the flute board. If you’d prefer a more premium finish, better results are achieved by printing onto a paper to cover the surface of flute board.

It’s also possible to use a mix of different printing methods on your corrugated packaging project. For instance, the inside of your box can be litho printed with a full colour design, adding a ‘wow’ factor upon opening, with the outside flexo printed with a more simplified design for graphic impact.

Progress have over 25 years experience producing corrugate packaging of all types, and are perfectly placed to help you navigate this complex but very important aspect of production. Here we share five of the most common printing methods suitable for custom cardboard packaging.

Flexographic printing, or flexo print for short, is a process that uses rubber-faced rollers etched with your design which prints directly on the corrugate board by being pressed onto the surface. Flexo printed custom cardboard packaging is suited to more simplified graphics and branding styles, but can achieve good solid colour coverage using virtually any shade. Production quantities using this process are most economical when manufacturing between 500 and 1,000 custom printed cardboard boxes.

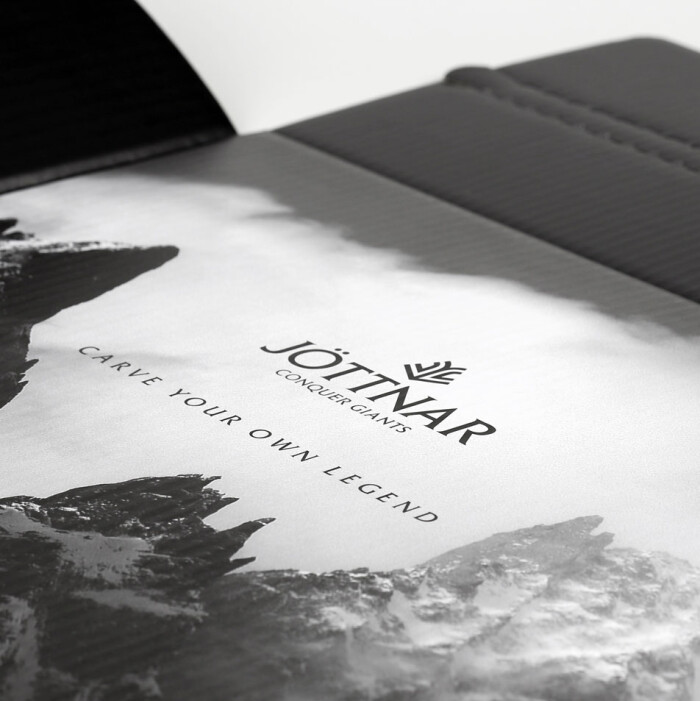

Lithographic printing, or litho print for short, is a process usually used for producing full-colour corrugated packaging designs. The print is first reproduced onto bespoke paper and is then laminated or duplexed to the surface of the flute board. This printing method can also be adapted for reproducing special colours, or spot colours as they are sometimes referred to, such as metallics or fluorescents as well as specific colours to match your brand.

Litho printed packaging is more costly than flexo printing due to the complexity of pre-production set-up and post-print finishing. This method does however, give a high quality finish, is better for reproducing more detailed graphics and is also easily tailored to suit your specific brand style. Using the litho process for producing custom corrugated packaging is achieved by printing onto thinner sheets of paper which are then glued to the surface of the corrugated flute board. Custom litho printed cardboard packaging quantities are economical from 1,000 boxes upwards.

Digital printing offers a number of valuable opportunities for personalised packaging boxes as the process doesn’t involve complex set-ups but retains the quality and flexibility of the litho printing method. Digital print is based on a four-colour printing process, enabling image reproduction to be achieved as well as large areas of flat, solid colour. The process also offers the ability to use surface varnishes, enabling visually dynamic gloss finishes that are more difficult to achieve using other print processes. Another key benefit (to custom litho printed packaging) is that quantities start at 250 upwards, making it perfect for formats such as personalised mailer boxes or shipping cartons which is great for start-up brands looking for a luxurious finish on a low number of units.

Silkscreen printing, otherwise known as screen printing, is a process that achieves reproduction of precise flat colours by pushing ink with a rubber squeegee through a screen made of fine mesh material to create a visual design on the corrugated surface. This process is most suited to flat colour, fine detailed artwork that would be too complex for a more simplified process such as flexo printing.

Screen printing is best suited to high visual impact packaging and is more economical to produce on smaller manufacturing quantities. Printing inks used for this process particularly suit corrugated flute boards as the inks sit on the surface of the material, allowing colours like opaque white to appear visually stronger and more defined. Custom screen printed packaging quantities start at 250 units, which makes this process perfect for formats such as bespoke mailing cartons, packing cases, subscription boxes, shipping boxes and bottle packs.

Foil blocking, or foiling for short, is a premium process that can be used on corrugated packaging, but only when firstly applied to thinner sheets of paper before being laminated to the surface of the corrugated flute board. Producing custom foiled packaging boxes involves metallic or flat colour pigment foils which are applied using a heated metal die that transfers the design by stamping it onto the paper surface. Reserved for larger production quantities starting at 1,000 upwards, custom foiled boxes are normally used on more high-end / luxury projects such as corrugated e-commerce packaging for fashion, beauty and fragrance brands.

Step 3:

Specify a material

Custom cardboard boxes are produced using a material called flute board, also known as corrugated board.

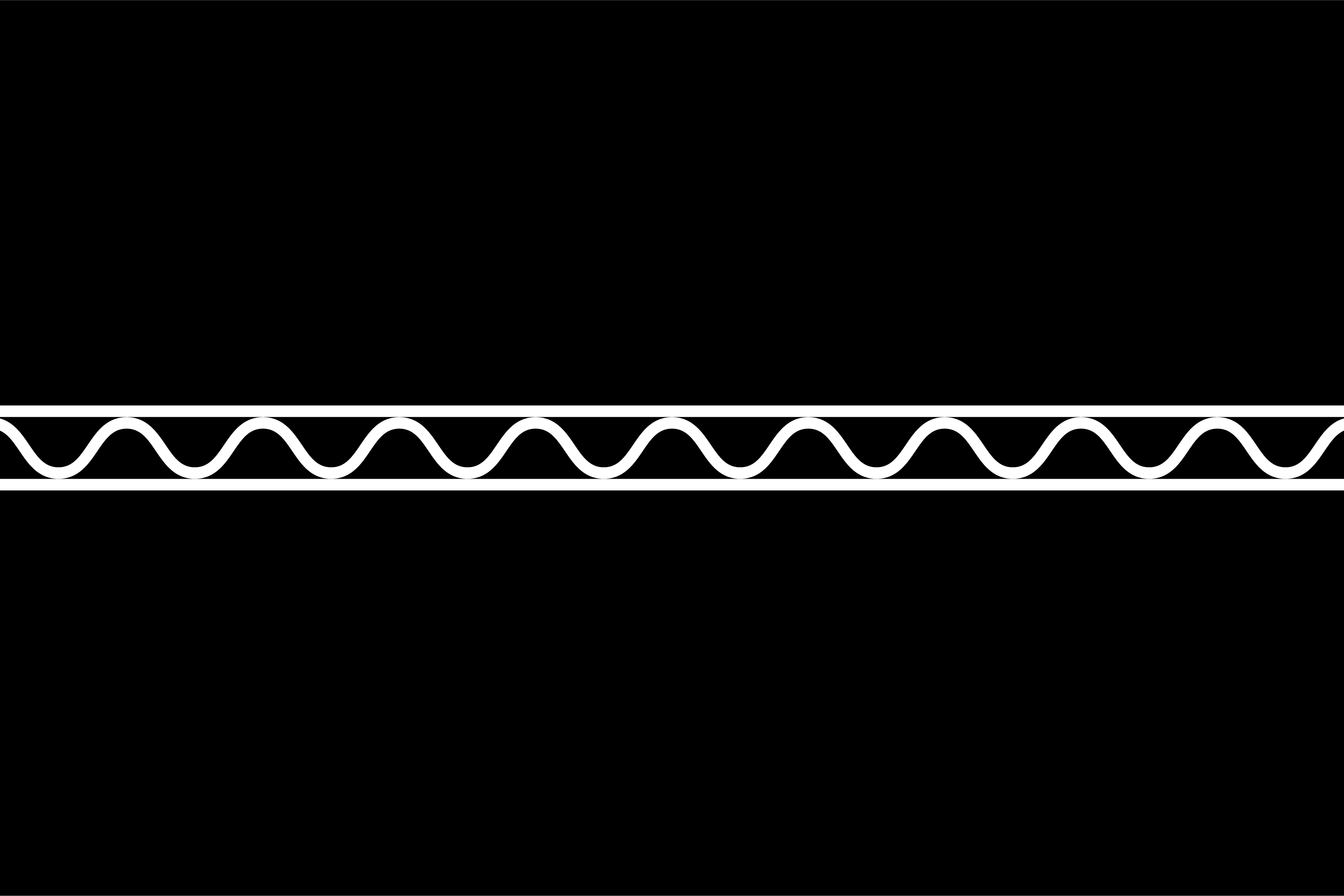

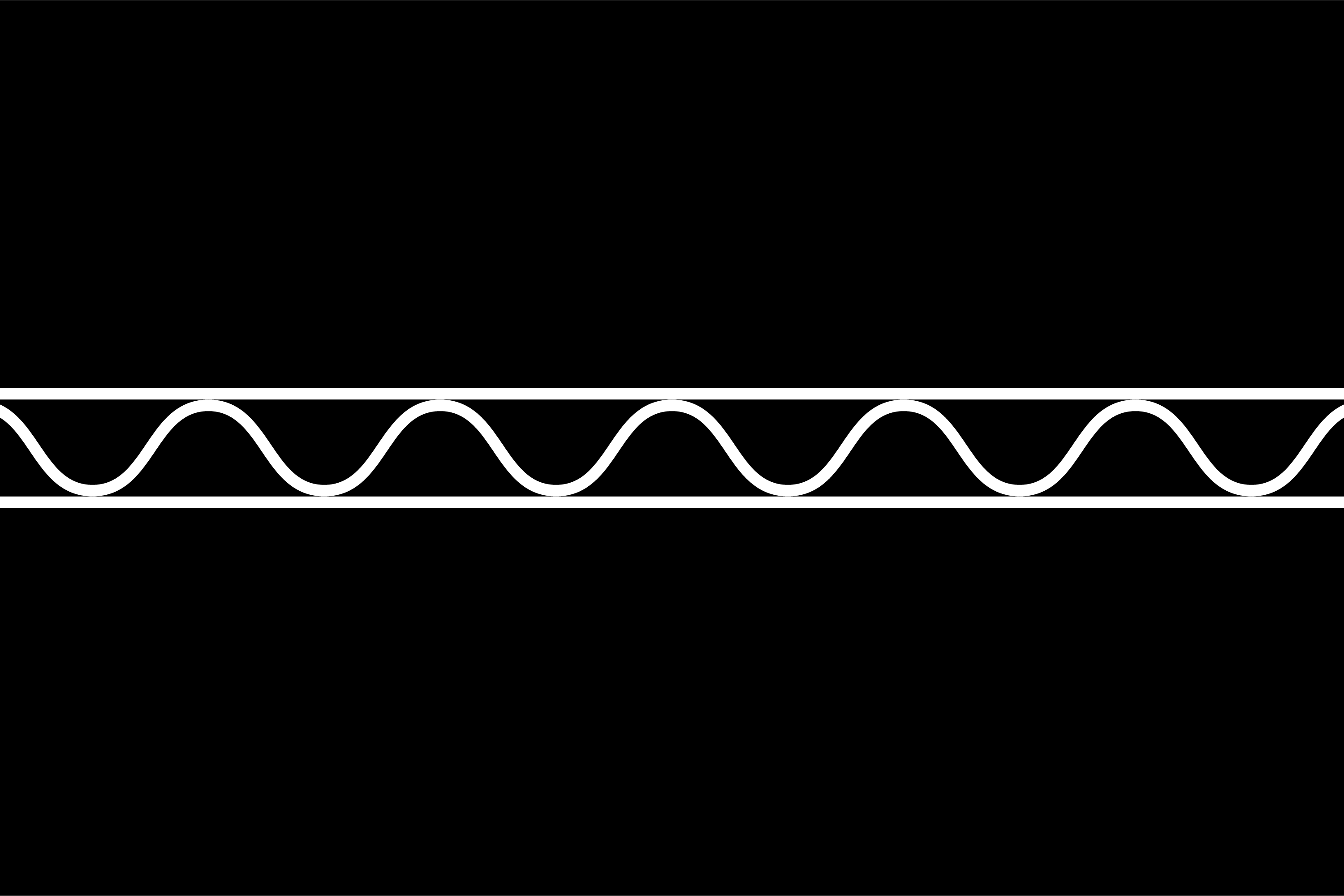

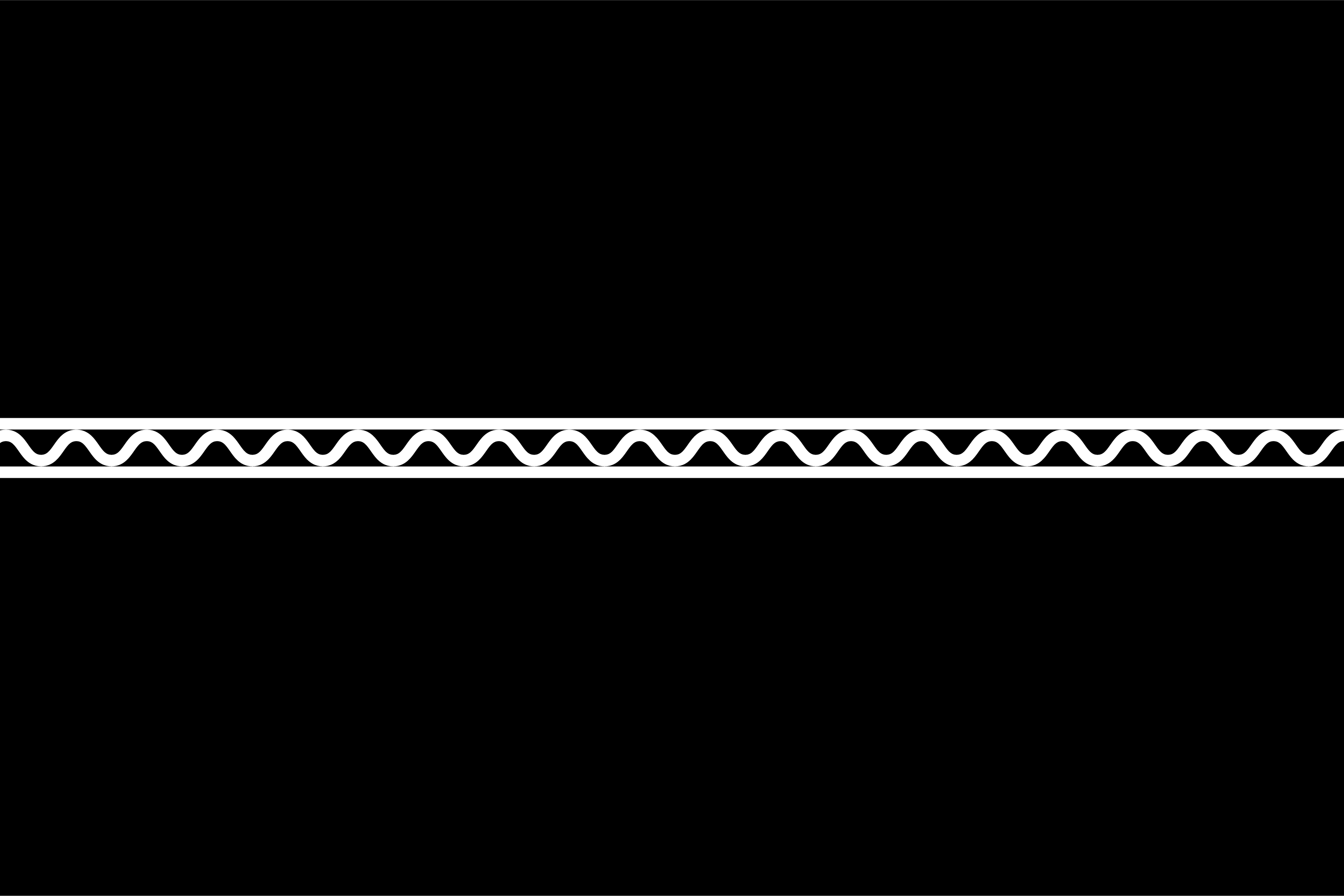

The material is made with three layers of card which are glued together. The middle layer is ‘fluted’ which looks like wavy lines if viewed in profile, and has flat layers bonded to it above and beneath. This gives the composite board a more rigid and robust character making it a perfect substrate for producing packaging that needs to be protective as well as light-weight – such as mailing boxes, shipping boxes, transit boxes, subscription boxes and packing cases. If you are unsure which grade of fluted corrugate would be best for your packaging we are happy to help by advising on the grade to suit your products based on the weight of the contents and the type of finish you are aiming to achieve on your box.

When specifying corrugated cardboard there are two key elements to consider – which type of flute board, and the best grade of lining paper to use.

Corrugate flute boards

Typically there are four grades of corrugated cardboard that we use in packaging production. Each are sustainable and made from fully recycled material – all have slightly different properties and characteristics.

E-flute corrugate is approximately 1.5mm thick making it one of the thinnest of the standard flute boards for producing custom packaging boxes. This makes it one of the best surfaces to print on – the material also has excellent compression strength and crush resistance.

B-flute corrugate is approximately 3mm thick and is the most widely used for producing custom packaging boxes. This grade of flute offers great all round properties regards printability, strength and crush resistance.

EB-flute corrugate is approximately 4.5mm thick. As the name suggests it combines E and B flutes into a single double walled material. It is generally used for making larger sized boxes that contain fragile or heavy contents. When applying print to this material, pre-printed sheets are laminated to the E-flute side to reduce the visual prominence of the ‘wavy lines’ on the print – giving a smoother and more refined finish.

Micro-flute corrugate is approximately 0.75mm to 0.9mm thick. As the name suggests, this makes it a thinner and more delicate material than other flute grades. This material has an excellent printing surface and is used widely for custom printed carton boxes. It can be litho printed onto directly without needing to be laminated, making it perfect for retail packaging. This flute is also used commonly for fragrance and cosmetics packaging to line the inside of light-weight carton boxes to protect more fragile products, or for shallow boxes to give more rigidity such as collections or tester sets. Micro-flute corrugate is available in black and white as standard, as well as in a limited range of colours if required.

Lining Papers

Lining paper, or simply the liner, is a layer of paper applied to the corrugate flute board to give a more defined surface finish. These papers are for printing and applying visual branding onto a box. Lining papers can also be used unprinted to add a more refined finish to the reverse side of the corrugate board. This is for instances such as lining the inside of an e-commerce box in white Kraft paper, making this more visually pleasing than the standard brown of the corrugate reverse. Whichever lining paper you choose, we ensure that it is sustainably sourced, meaning your custom cardboard boxes are eco-friendly and even FSC® accredited should you require.

This paper is sustainably manufactured from softwood trees using ‘virgin fibres’. It is both the strongest and also the most highly versatile material regarding printability. Kraft paper is most commonly used as a lining paper when producing custom packaging that is branded / printed with a bespoke design. Kraft paper is available in both natural (brown) and white shades.

Test paper is most commonly used for lining the inside of a box when there’s no print required. This material is not suitable for printing which makes it more economical than Kraft paper. Test paper is natural (brown) in colour.

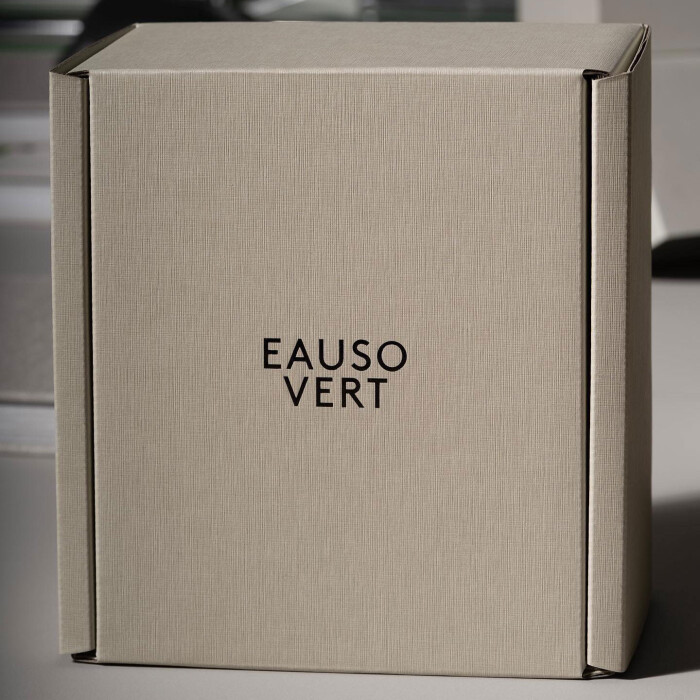

It is possible to use custom papers to achieve different finishes on corrugate cardboard packaging which we can advise on should they be of benefit to your project. Options available range from dyed / coloured boards and embossed / textured papers, to more creative papers that would traditionally be seen on premium rigid boxes. These can be used creatively as more visually striking lining papers for packaging on the inside or outside of a custom cardboard box.

Step 4:

Add a closure method

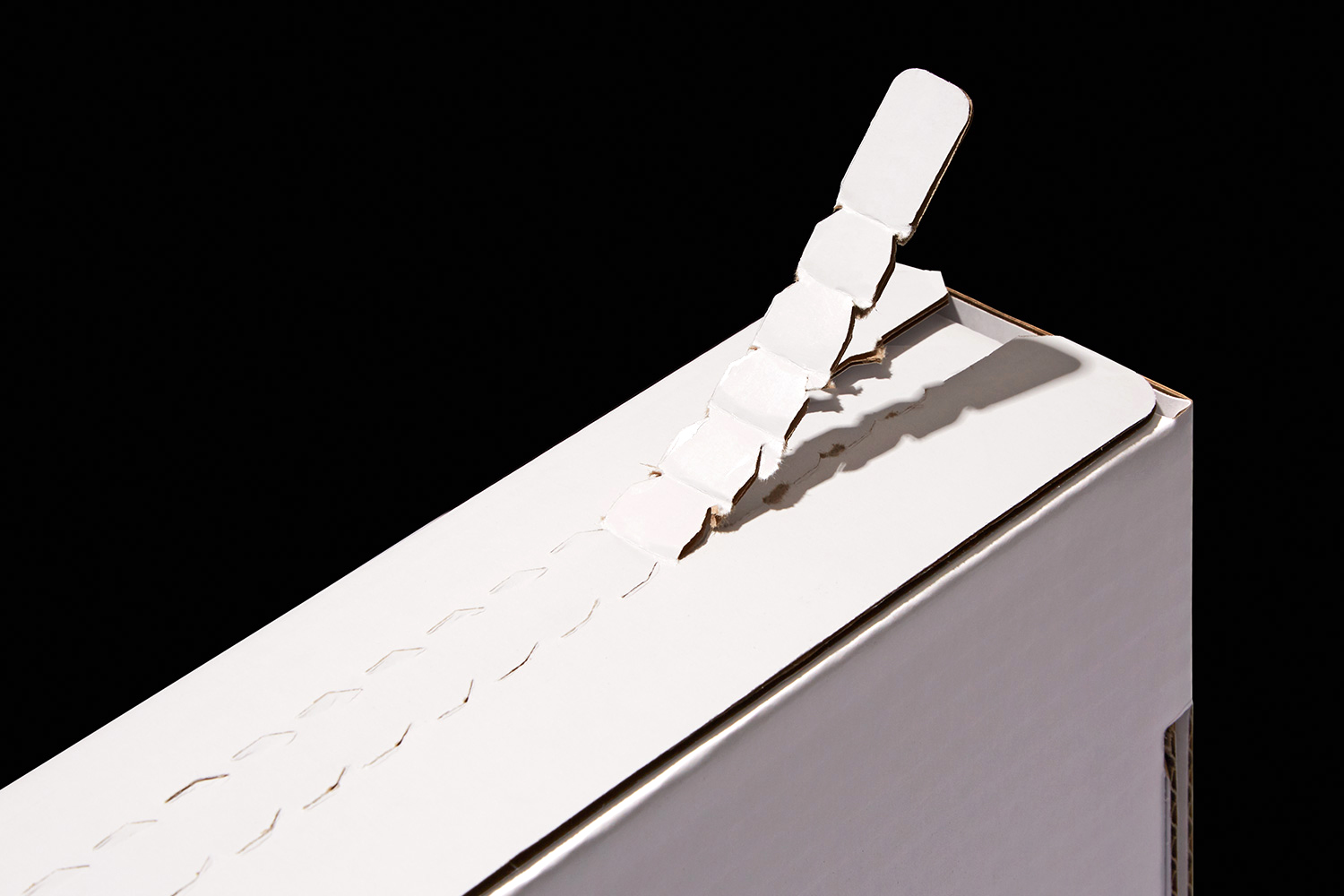

For custom corrugated packaging boxes such as e-commerce, shipping or mailer boxes, choosing the best closure to suit the use of your pack is an important decision – especially considering it will often be the method also used for opening the box.

Tuck-in tabs are a good option where its important to re-seal the cardboard box after its initial opening. If you’re hoping to create more of a ‘wow’ factor, a crocodile tear-strip, or peel and seal closure as they are also referred to, can add theatre to the opening of a box. Here we highlight four of the most popular closures we use in production of custom cardboard boxes.

Peel and seal tear strip closures are great options if you don’t want to use packaging tape as an additional process to close a corrugated box. This type of closure also means that consumers can easily open the box by just pulling the tear strip – especially if incorporated into mailer and retail shipping boxes. If products need returning using the same box, we can also add an extra seal strip for customers to use when returning the packaging.

A great option if you’re looking to create a self-closing box without the need for glueing, is to engineer tuck-in tabs into the box. This is a popular method if you would like your box to be completely eco-friendly, and is a common choice in the retail industry where a more secure closure may not be required.

Packaging tape is a highly popular method for securely closing corrugated boxes, and is particularly common for sealing open-flap packing cases. We produce eco-friendly custom packaging tape using natural (brown) or white Kraft paper which can be printed in virtually any colour to match your brand style.

Stickers are a highly versatile closure for bespoke packaging. We can fully customise printed stickers to virtually any size or shape. For more luxurious options we can foil block, blind-emboss or deboss your design. Stickers can be supplied cut to shape individually, or on rolls suitable for more automated application.