Custom advent calendars:

Design to delivery

Progress are an established advent calendar manufacturer providing a wide range of options to enable both design and production to be customised to suit your brand. This specialist format has seen a resurgence in popularity in recent years, particularly across the luxury sector, with brands drawing attention to their products using this highly versatile form of packaging.

Our turnkey service means Progress can produce bespoke personalised advent calendars to the highest standard and specification – from design and concept, specifying and budgeting, prototyping and engineering, printing and production, to fulfilment and worldwide delivery.

Popular bespoke advent calendar formats include; beauty advent calendars, perfume advent calendars and fragrance advent calendars. We can produce custom advent calendars in a range of sizes, shapes and styles to suit your brand and product range. If you’re thinking about sustainable materials and processes for your custom advent calendar, Progress have got that covered too. Just talk to our packaging experts who are on hand to help, guide and advise you through every step of your advent calendar production.

Step 1:

Creating a unique advent calendar format

The key to deciding on the best format is selecting a style that delivers a ‘theatre of opening’ that suits the personality of your particular brand and products.

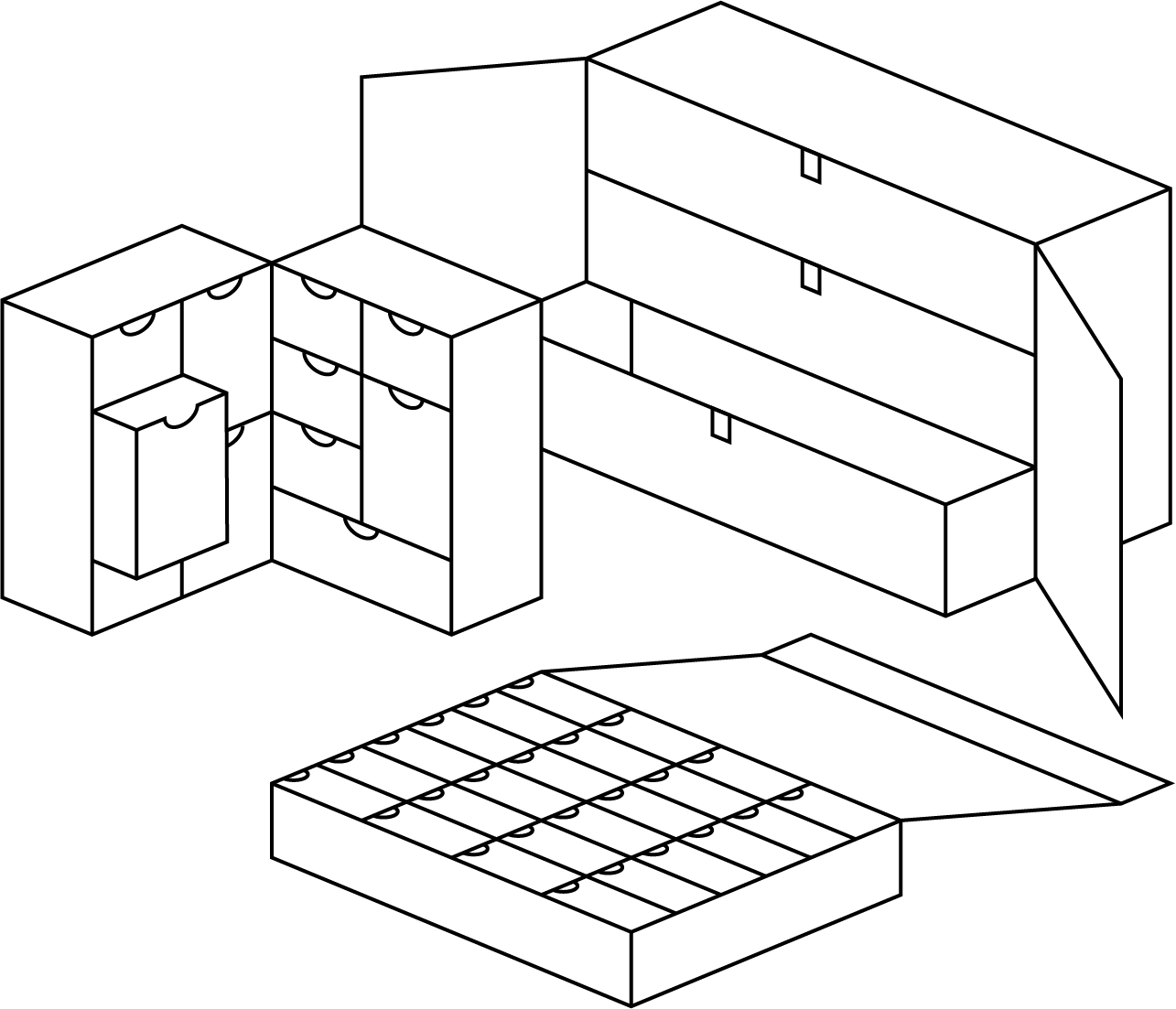

Three of the most popular luxury advent calendar formats are:

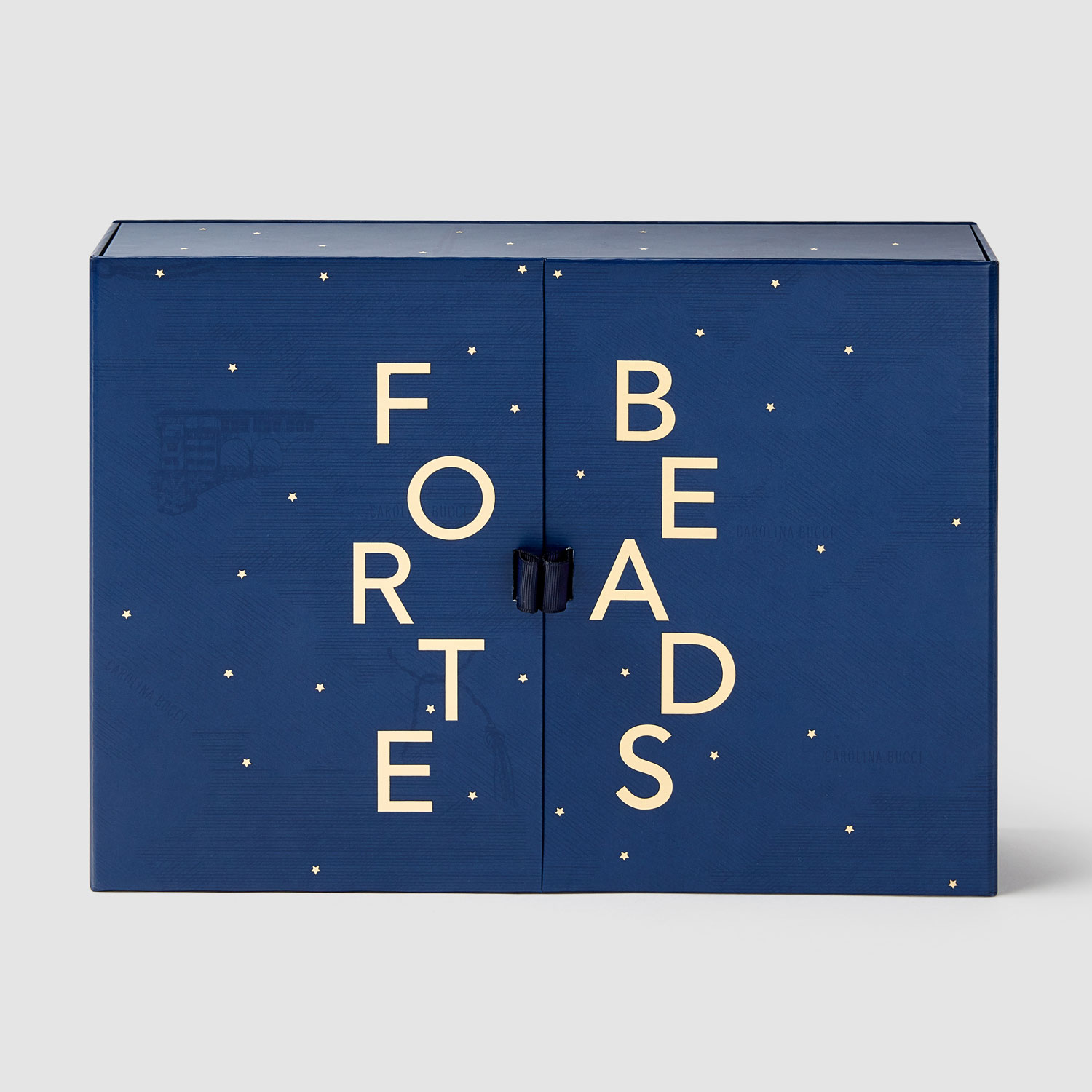

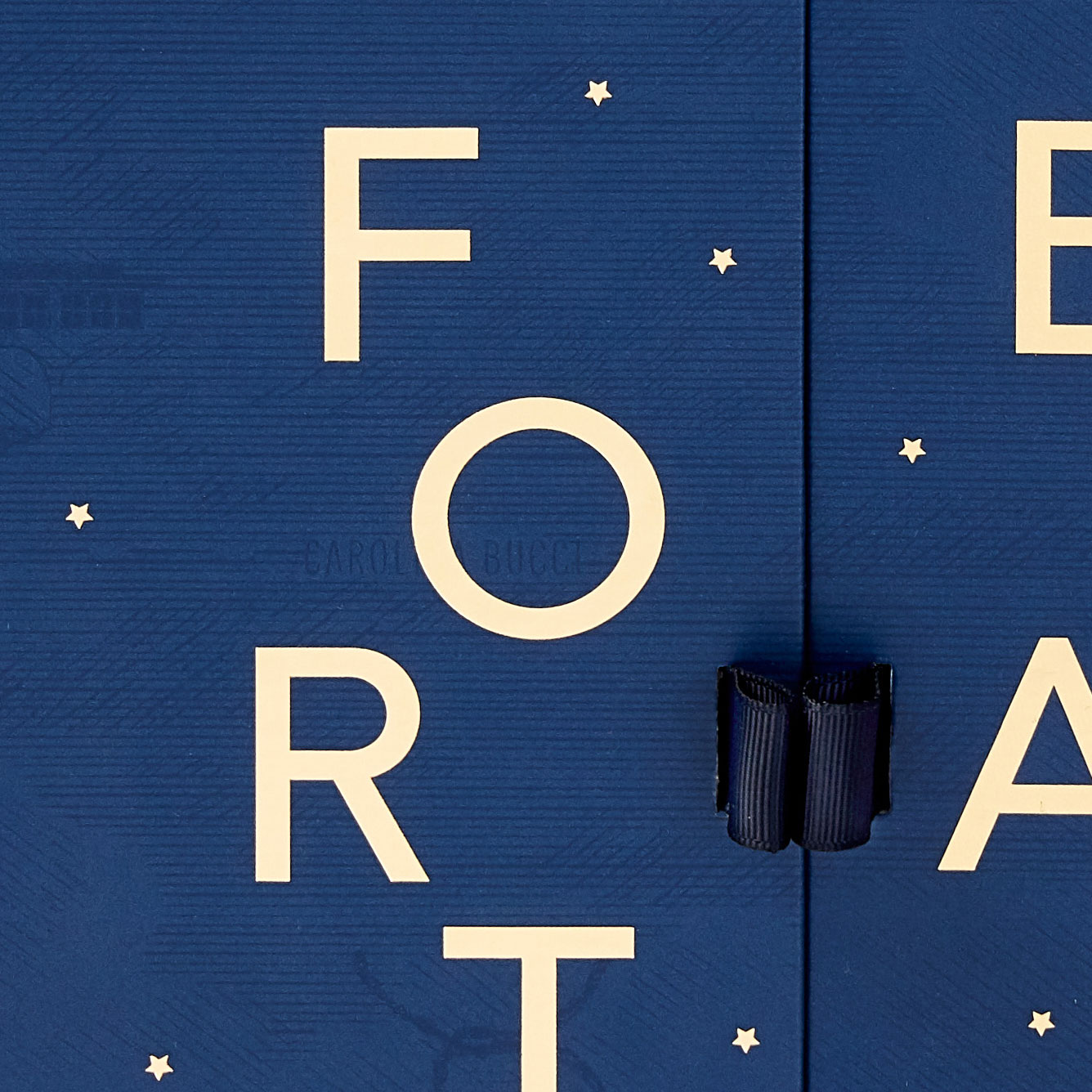

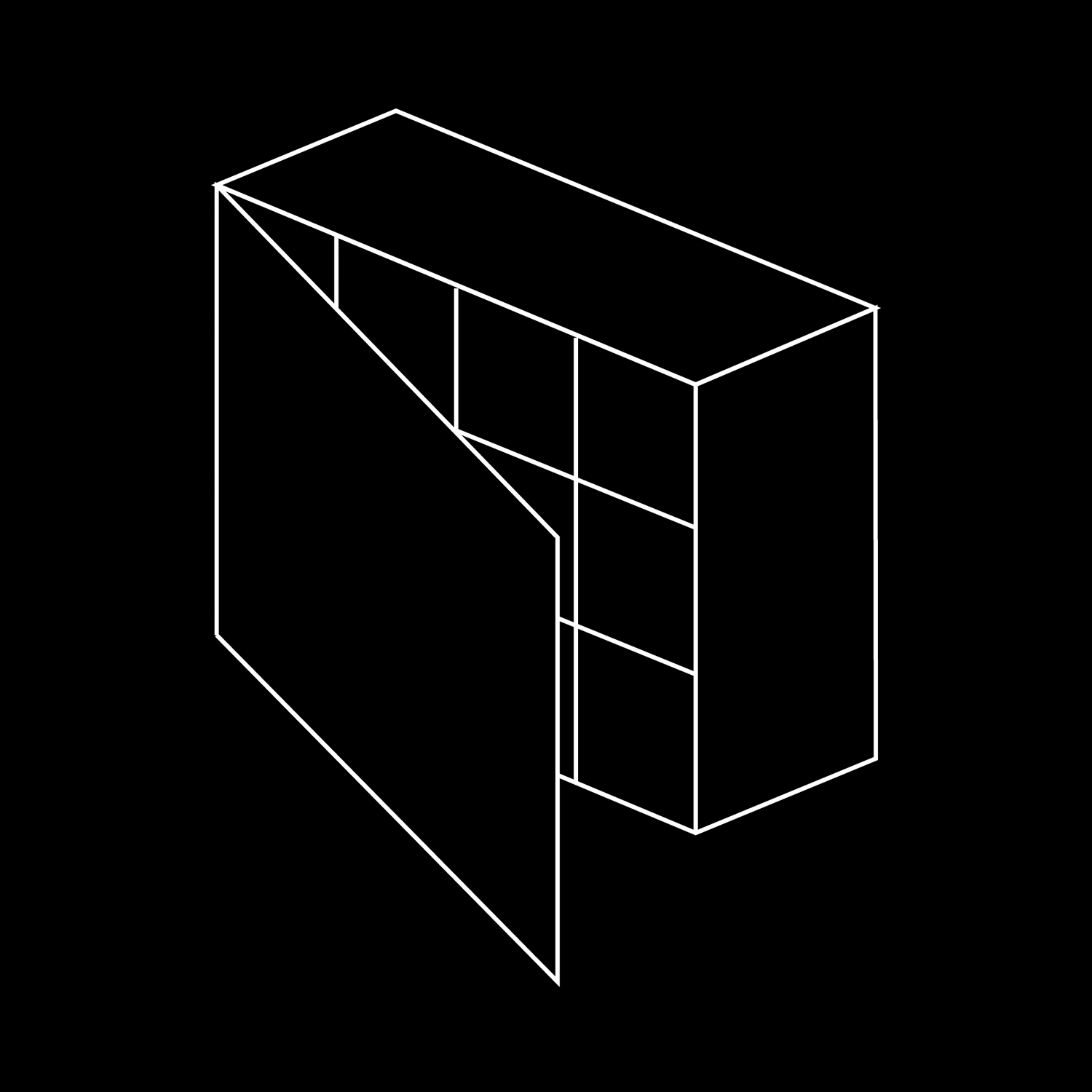

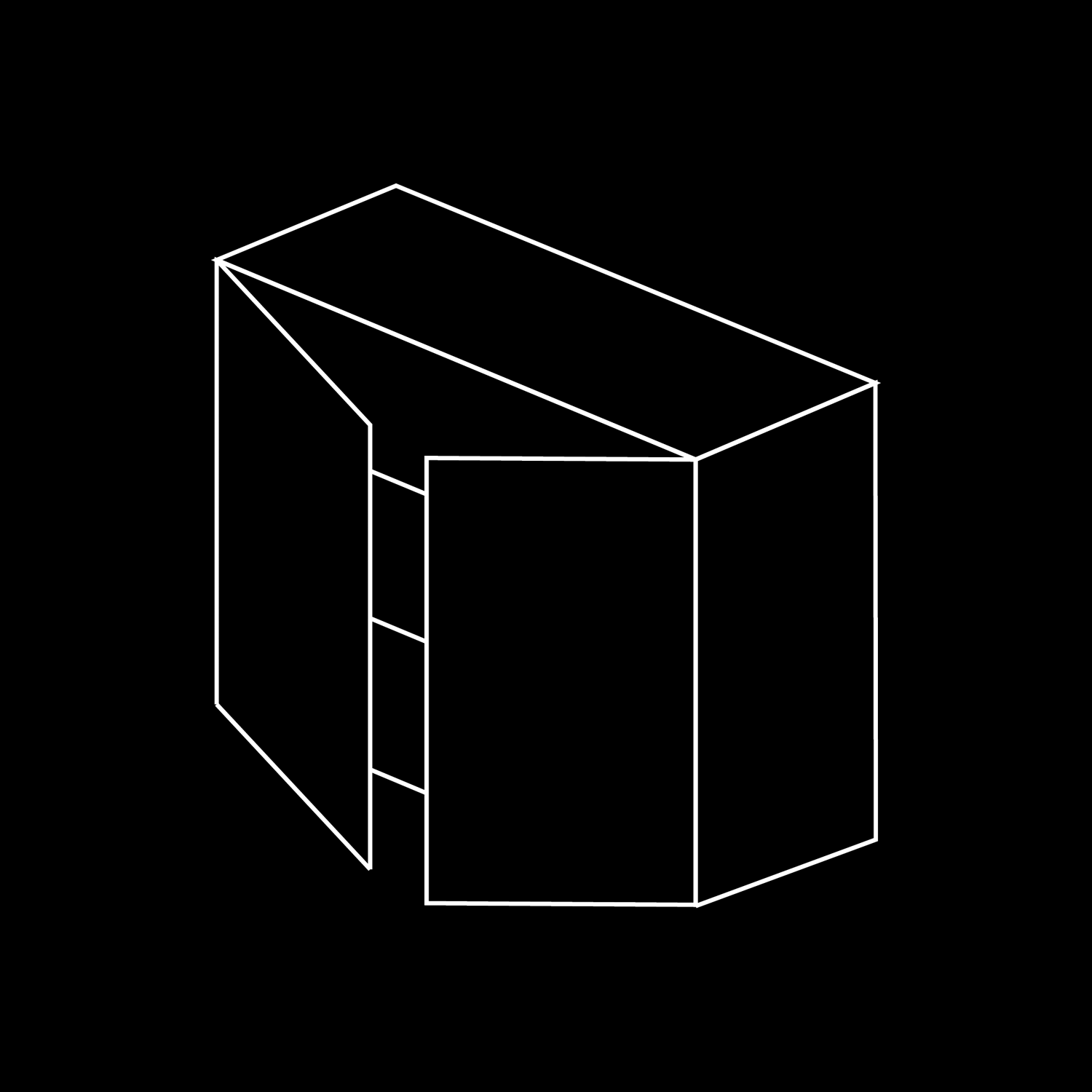

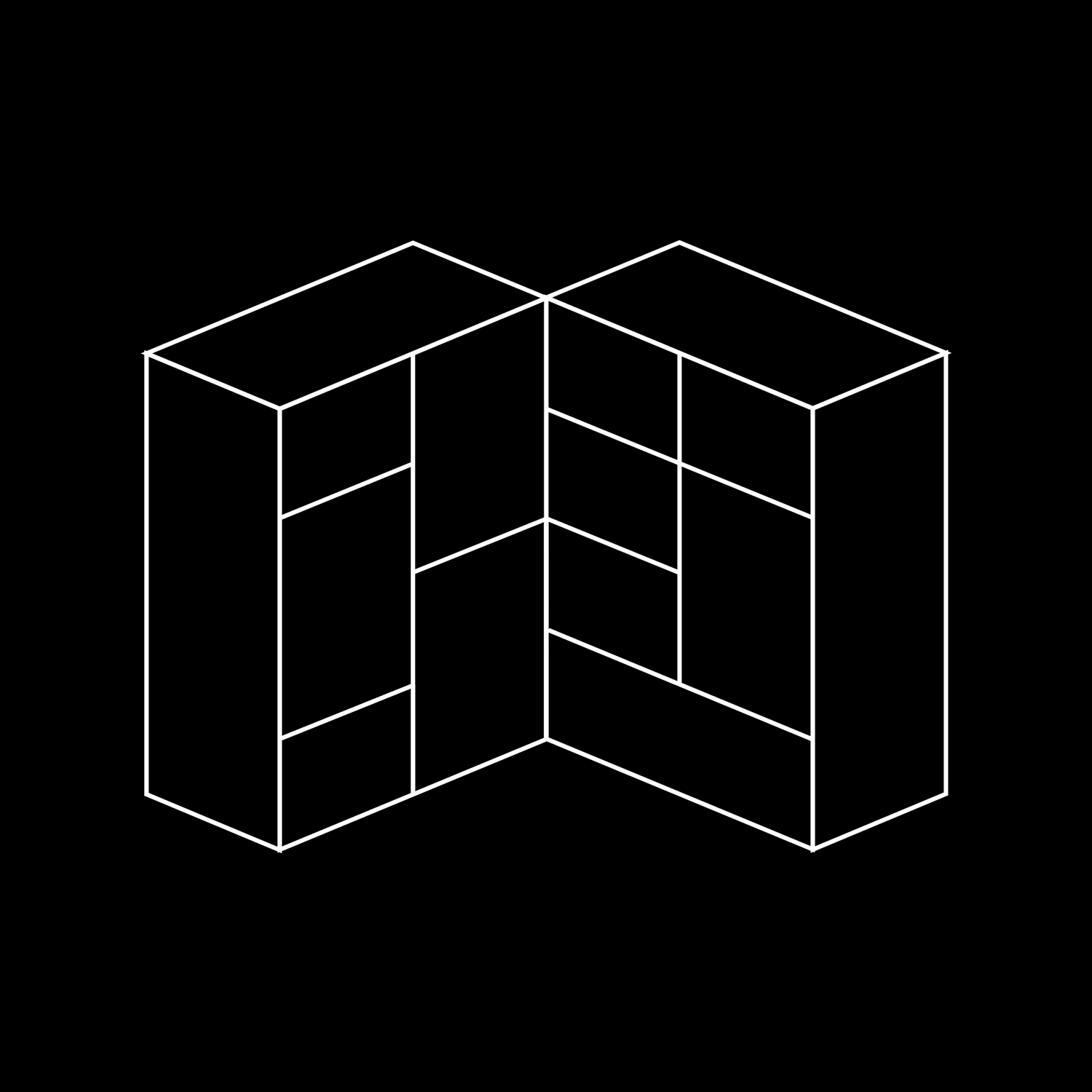

Single door style means your custom advent calendar opens with one panel from the front to reveal the drawers behind.

Double door style means your custom advent calendar will have a split front opening to reveal the drawers behind.

Book style means your custom advent calendar will have a split front opening with the drawers behind each side.

Step 2:

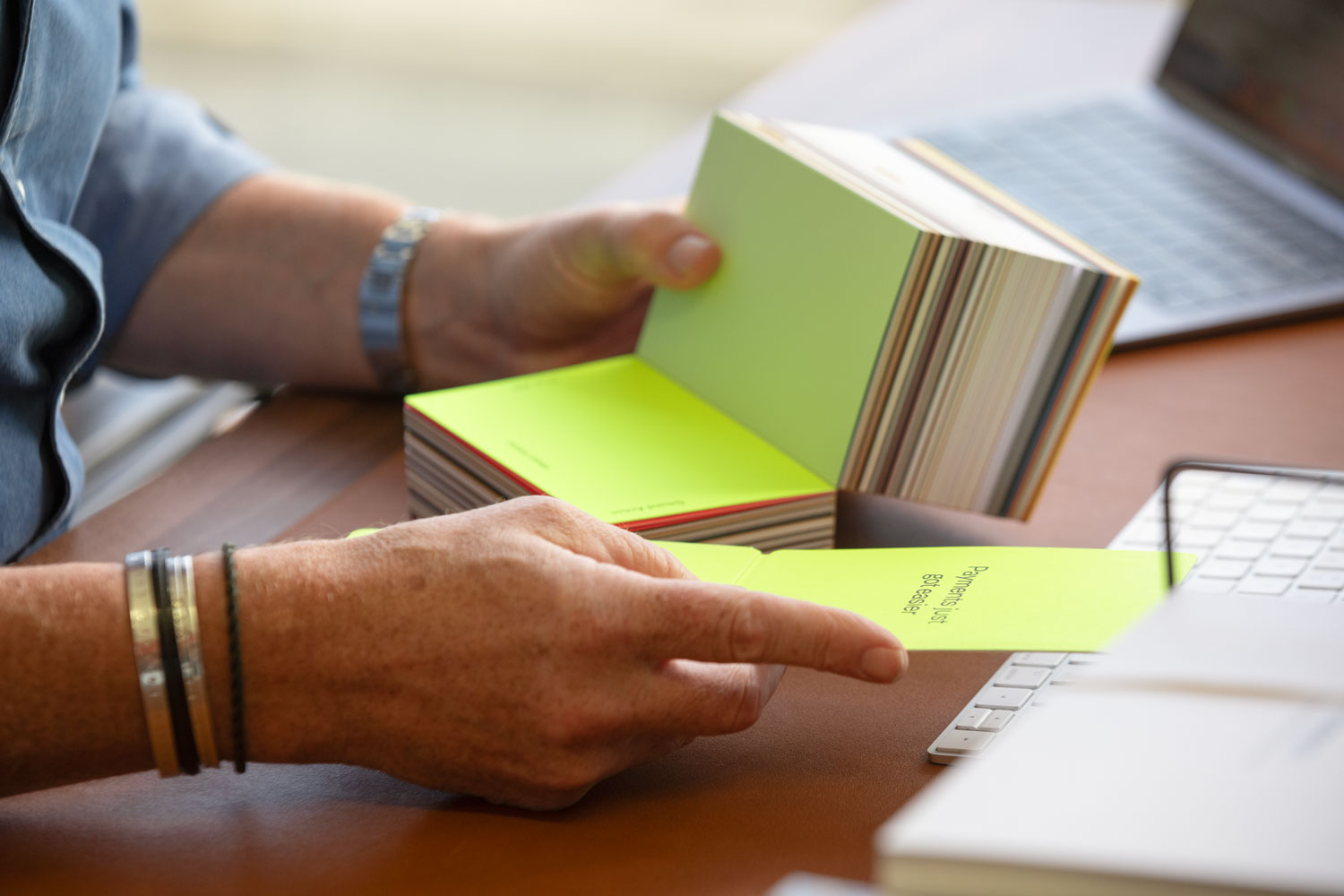

Showcasing your products in custom advent calendar boxes and drawers

Choosing the most suitable type of drawer to hold your product is an important part of specifying your deluxe advent calendar.

Four of the most popular ways to house your products in a personalised advent calendar include:

Rigid drawers create a more robust and luxury feel to your custom advent calendar. Constructed using a more robust cardboard core, rigid drawers can be covered with a variety of different coloured or textured materials to match your brand or design.

Stacked cartons are a more cost-effective manufacturing process for creating boxes to house products in your custom advent calendar. Carton boxes are constructed using a thinner weight card, and can be made in custom sizes using a wide range of coloured or textured materials to match your brand or design.

Internal dividers with cartons

Internal dividers with cartons is a mid-level cost option for making custom advent calendars. Constructed by die cutting and folding flute board to create internal compartments, cartons are then made to go inside the compartments to create drawers to house your product. Carton box drawers are constructed using a thinner weight card, and can be made in custom sizes using a wide range of coloured or textured materials to match your brand or design.

Internal dividers can be easily manufactured to create compartments to house your products. Creating a uniform structure within the advent box, is a very cost-effective way to divide the internal space of your custom advent calendar, as they can be adjusted to accommodate the size of your product.

Step 3:

Adding premium finishes to your custom advent calendar printing

Specifying your designer advent calendar, selecting the best branding process and choosing the most suitable papers and finishes can be overwhelming.

At Progress we have over 25 years experience as packaging manufacturers. We’re here to help our customers navigate the printing process and material options available which include the following:

Lithographic printing, or litho print for short, is a process usually used for producing full colour advent calendar designs. The print is first reproduced onto bespoke paper and is then laminated or duplexed to the surface of the flute board. This printing method can also be adapted for reproducing special colours, or spot colours as they are sometimes referred to, such as metallics or fluorescents as well as specific colours to match your brand.

Litho printed advent calendars are more costly than digital printing due to the complexity of pre-production set-up and post-print finishing. This method does however, give a high quality finish, is better for reproducing more detailed graphics, and is also easily tailored to suit your specific brand style. Using the litho process for producing custom advent calendars is achieved by printing onto thinner sheets of paper which are then glued to the surface of the corrugated flute board. Custom litho printed advent calendar quantities (MOQ’s) are economical from 1,000 units upwards.

Digital printing offers a number of valuable opportunities for custom advent calendar manufacture, as the process doesn’t involve complex set-ups but retains the quality and flexibility of the litho printing method. Digital print is based on a four colour printing process, enabling image reproduction to be achieved as well as large areas of flat, solid colour. The process also offers the ability to use surface varnishes, enabling visually dynamic gloss finishes that are more difficult to achieve using other print processes. Another key benefit to digitally printing custom advent calendars is that quantities start at 250 upwards, making it perfect for a luxurious finish on a low number of units.

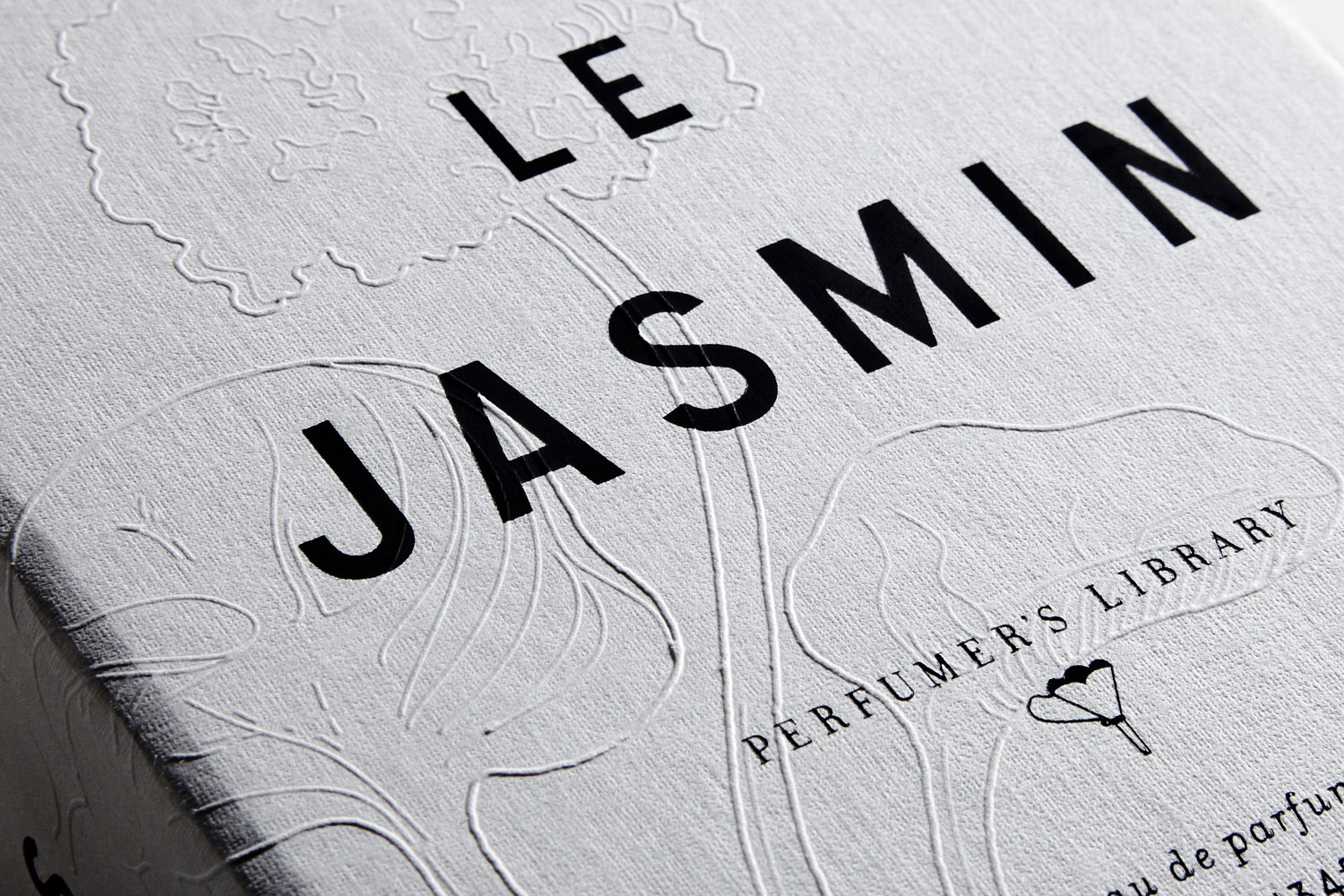

It is possible to use specialist papers to achieve different finishes on your custom advent calendar, which we can advise on should they be of benefit to your project. Options available range from dyed / coloured boards and embossed / textured papers, to more creative papers that would traditionally be seen on premium packaging. These can be used creatively as more visually striking options, on the inside or outside of your custom advent calendar.

Foil blocking, or foiling for short, is a premium process that can be used on custom advent calendars, either by firstly applied to thinner sheets of paper before being laminated to the surface of a rigid board lining, or by applying directly onto carton-weight boards. Producing custom foiled advent calendars involves metallic or flat colour pigment foils which are applied using a heated metal die that transfers the design by stamping it onto the paper surface. Reserved for larger production quantities starting at 1,000 upwards, custom foiled advent calendars deliver a more high-end / luxury aesthetic.

Embossing is a premium process that can be used on custom advent calendars by pressing a design into paper or cardboard to create a three dimensional effect. The process produces best results when using simple linear graphics such as text, logos and other branding assets.

Laser cutting is a premium process that can be used on custom advent calendars to create intricate ‘cut-out’ designs. Incorporating laser cutting into your custom advent calendar involves transferring your design onto paper by laser beam which burns through the paper surface, creating a precise finish which is perfect for delicate / intricate designs. Reserved for larger production quantities starting at 1,000 upwards, custom laser cut advent calendars give a more high-end / luxury aesthetic.

Die cutting is a process used to create unique shapes and designs for bespoke advent calendars. This could mean making inserts to secure your products within internal drawers, fitments to protect delicate products, or to build the internal structure of your advent calendar to make the shape more customised to your brand. Please get in touch if you’d like to discuss the different options available for using die cutting in your custom advent calendar manufacture – our team are here to help.

Step 4:

Making your advent calendar eco-friendly

When considering the specification details of your luxury advent calendar you will need to asses the importance of its eco-friendly credentials, as this will relate to the material you specify for manufacturing.

Progress can make every aspect of your custom advent calendar bespoke to your requirements and can advise and help you navigate the options available for taking the most eco-friendly approach. Aspects to consider include:

Making your bespoke advent calendar using no plastic means manufacturing with materials and substrates with no plastic present either in the principle substrates or coatings. Please get in touch if you’d like to discuss ways in which we can exclude plastics from your custom advent calendar manufacture – our team are here to help.

At Progress we are committed to manufacturing sustainable packaging using economically-sound methods that minimise negative environmental impact, and we are pleased to offer a variety of paper ribbon alternatives that can transform the recyclability and eco credentials of your custom advent calendar. Paper ribbon is available in a variety of thicknesses and colours. They are made by weaving thin strands of twisted paper into a braid / ribbon format. The technique gives the look and feel of traditional ribbon but without the negative environmental impact regarding their recyclability. Please get in touch if you’d like to discuss the different paper ribbon drawer pull / opening options available for your custom advent calendar manufacture – our team are here to help.

To transport and deliver your custom advent calendar to customers, a cardboard packing case is the safest and most secure format. These box formats are usually made using thicker corrugate flute material and feature flaps to both the base and lid, which can either be taped closed or incorporate a slotted closure mechanism. A number of printed branding options are available for this type of box, enabling them to be used at point of sale if required. Please get in touch if you’d like to discuss the options available for your custom advent calendar packaging – our team are here to help.

Single stream recycling means that your custom advent calendar can be disposed of after use without being broken into different components, which would need to be processed separately during recycling. Please get in touch if you’d like to discuss recycling options available for your custom advent calendar after life – our team are here to help.

There is a large range of eco-friendly papers and boards we can recommend for using to manufacture your custom advent calendar. These papers and boards are made using ‘virgin fibre’ and are normally FSC® certified. Using materials that come with this certification affords you full confidence regarding the eco-friendly credentials of your custom advent calendar. It’s best to avoid any post-printing film lamination processes to ensure your box is both made using materials from sustainable sources, and is fully recyclable after use. For more information about FSC certifying your custom advent calendar, please refer to our Packaging Standards insight.