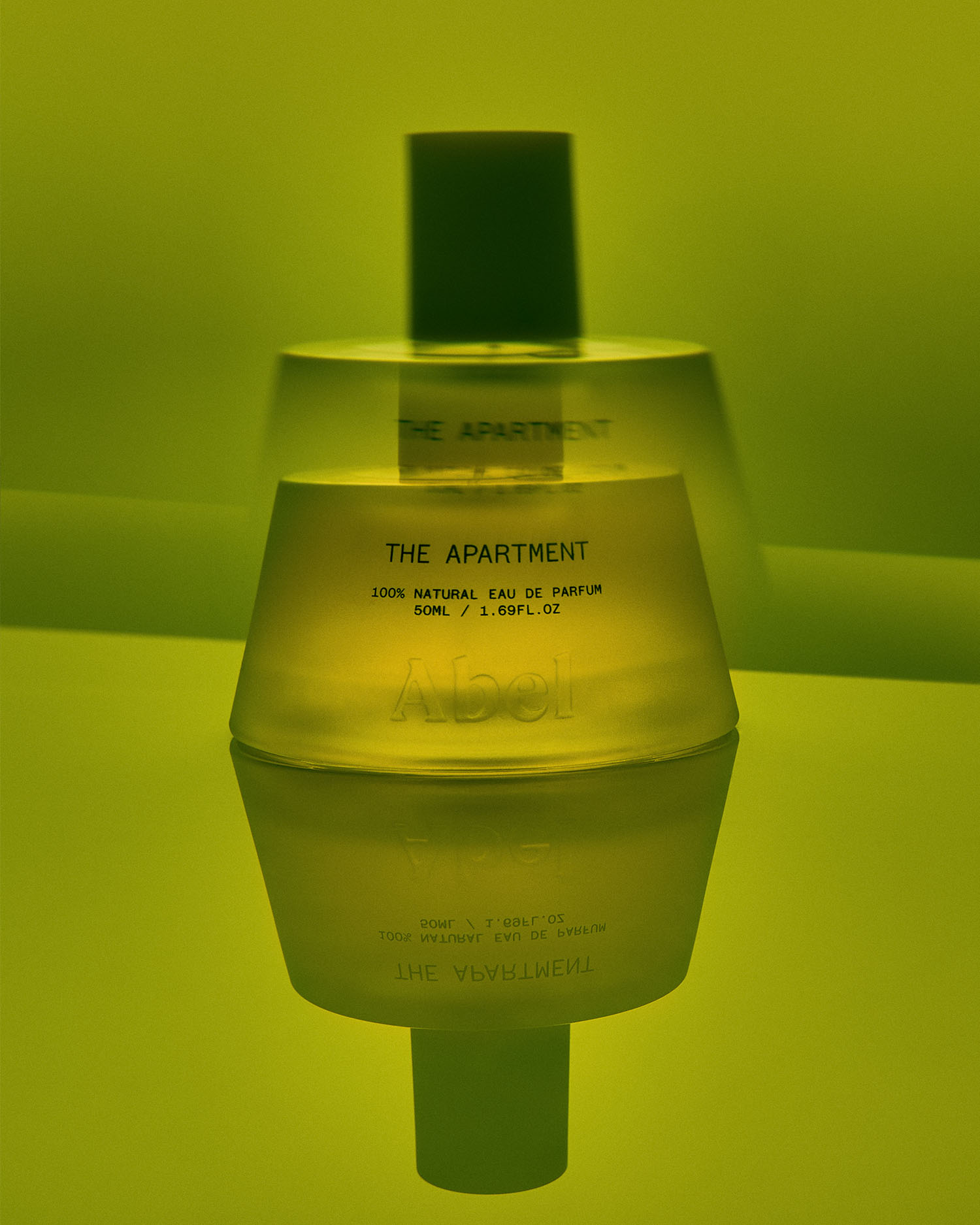

Abel Fragrance

Abel make completely organic, 100% natural perfume. They specialise in creating fragrances that challenge industry norms and provide biodegradable, environmentally responsible alternatives. As part of the development of the brand with Base Design, Abel reviewed their existing luxury paper-over-board packaging formats and transitioned to a carton-based system using bespoke made paper. This approach aligned more closely with their natural, low-impact ethos while enabling the creation of custom coloured papers, giving the range greater visual distinction beyond standard colours widely used within the fragrance sector.

Having worked with Abel as a long-standing manufacturing partner, Progress was again engaged to manufacture the new packaging range and advise on the change in format. The project focused on producing bespoke, custom-coloured paper cartons for both 6ml and 50ml fragrance formats, manufactured to Abel’s exact specifications and developed by Progress to deliver consistency across multiple SKUs. As part of this process, Progress consulted on and managed the whole custom paper manufacturing process, testing the paper within production and refining weights to achieve the optimum balance of tactility, strength and performance before integration into carton manufacture.

SUSTAINABILITY

Fully recyclable packaging. Manufactured from sustainable and responsibly sourced materials.

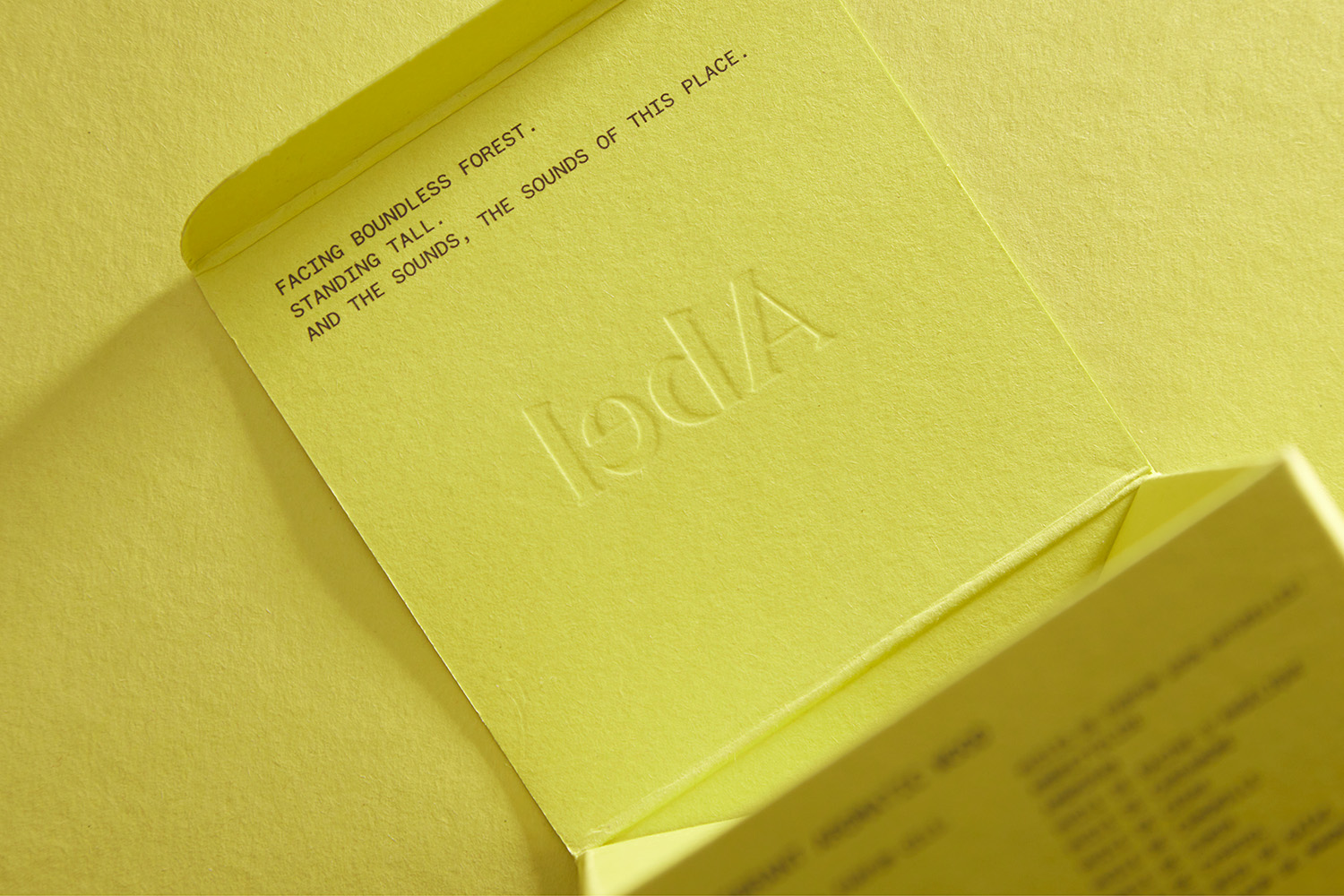

The 6ml fragrance cartons were manufactured using a 330gsm bespoke made paper, custom coloured for the range. These opposite tuck end cartons were printed in one colour (black) and sealed to one side. A blind deboss was applied to feature the Abel logo, used consistently across all cartons, alongside a single-position foiled logo applied in matching black. The cartons were die cut, creased and glued to one position, and were produced across 11 SKU variants.

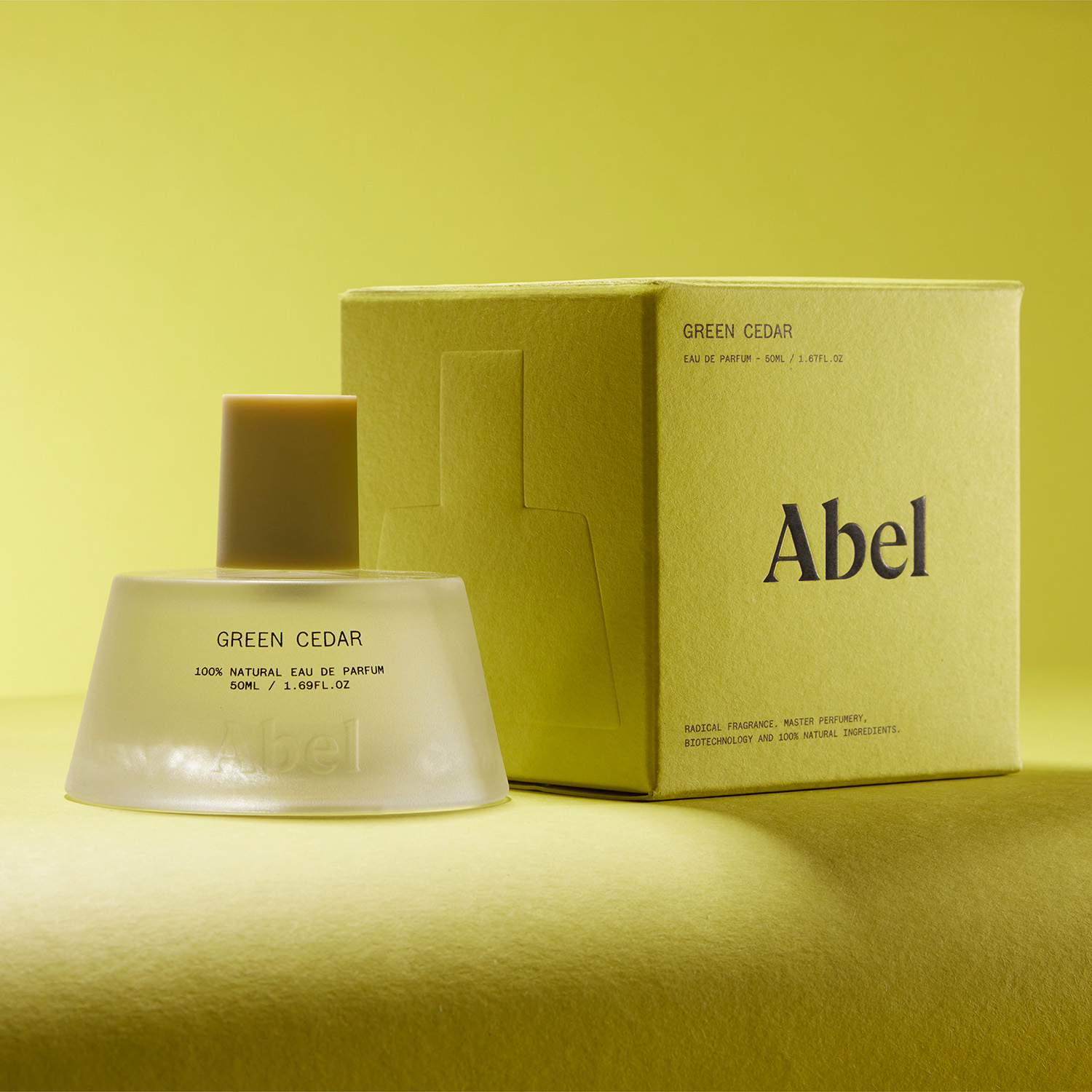

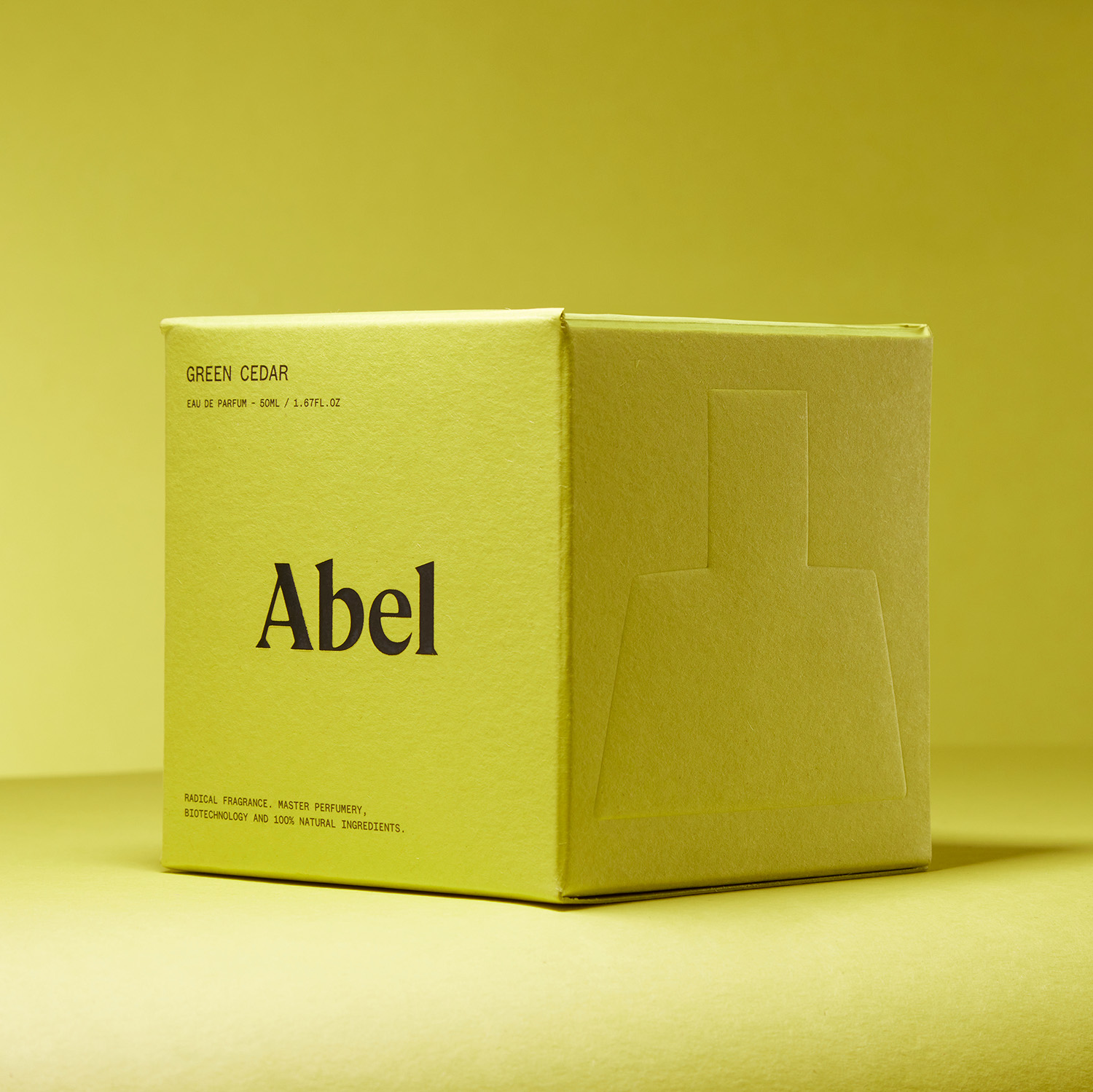

The 50ml fragrance cartons were produced using a heavier 450gsm bespoke made paper, again custom coloured to exactly match the wider range. These cartons were printed in matching colour and sealed throughout. A black matt foil raised emboss was applied to one panel for the logo, alongside a blind raised emboss to two panels featuring the bottle silhouette. The cartons were die cut, creased and glued to one position. To provide protection during transit, the 50ml cartons incorporate brown corrugated liners, specified to secure the bottle while maintaining a clean and minimal unboxing experience.

The production approach is designed to support ongoing growth while maintaining consistency in materials, finish and carton construction.

To learn more about the story behind this project and the custom paper making process see our insight.

The custom coloured paper gives the packaging range greater visual distinction beyond standard shades widely used within the fragrance sector.

‘Every decision we make, from fragrance formulation to packaging, has to align with our values. This new packaging reflects that thinking: carefully chosen materials, reduced impact, and a design that feels confident without being overstated.’

Frances Shoemack, Abel founder.